Case Studies

Backing the Boro: Paragon Rapid Technologies named new Middlesbrough WRFC kit sponsor

Dan Martin See Full Bio

Paragon Rapid Technologies – Quality Policy

Paragon Rapid Technologies – Quality Policy 5.1 steven See Full Bio

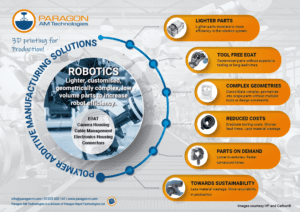

Infographic: Polymer AM for Robotics

This infographic highlights the benefits of polymer AM for applications in the robotics industry.

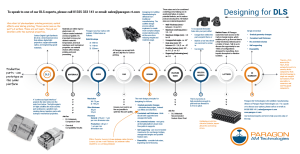

Designing for Carbon DLS Additive Manufacturing

This infographic outlines some considerations and the 5 basic principles for ensuring a successful design…

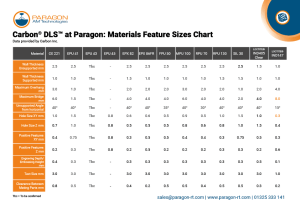

Carbon DLS at Paragon: Materials Feature Sizes Chart

Paragon Rapid Technologies offers 13 resins for part production using its Carbon Digital Light Synthesis…

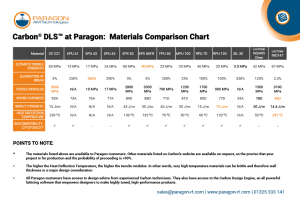

Carbon DLS at Paragon: Materials Comparison Chart

Paragon Rapid Technologies offers 13 production resins and 1 prototyping resin (not listed here) for…

The Paragon Texturing Portfolio: Look Better, Feel Better

Paragon Rapid Technologies offers a portfolio of standard textures for additive manufacturing processes. Simply choose…

Carbon DLS polymer additive manufacturing for medical devices

Designing for Polymer Additive Manufacturing: Some Considerations

Introducing Nathan George, Paragon’s new Business Development Manager for the Midlands

We're pleased to announce that Jim Ashby has been appointed Applications Development Manager for the…

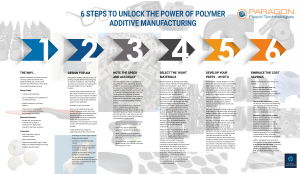

Infographic: Six Steps to Unlock the Power of Additive Manufacturing

Download our infographic. By following these steps, you can unlock the power of additive manufacturing…

Reaction Injection Moulding (RIM): Beyond Automotive

RIM, or Reaction Injection Moulding, is a low volume manufacturing process used to produce high-strength,…

Case Studies: Using HP MJF Additive Manufacturing in Automotive Engineering

The use of MJF in automotive applications with HP and Production Partners

The Apprentice Paragon Edition – Megan Thomas, You’re Hired!

My name is Megan and I am proud to have successfully completed an apprenticeship in…

Vacuum casting: bringing Industrial Products to market faster and for less

Involving the use of silicone moulds and polyurethane resins, vacuum casting offers several advantages for…