Digital Light Synthesis™

Carbon M2 Printers – 4 Printers

Lead time: 4 days

Build Platform (mm): 189 x 118 x 326

Accuracy: to ± 0.1%

Pixel resolution: 75 μm

Surface structure: Parts printed with Digital Light Synthesis™ are much more like injection-moulded parts. Digital Light Synthesis™ produces consistent and predictable mechanical properties, creating parts that are solid on the inside.

DLS Materials and Data Sheets

RPU 70

Tough, moderately heat resistant material with ABS-like properties including excellent durability.

MPU 100

Medical-grade Polyurethane. A unique combination of mechanical strength, biocompatibility, and sterilisability.

FPU 50

Impact, abrasion and fatigue resistant semi-rigid material that is a good choice for parts that must withstand repetitive stresses such as living hinges or friction fits.

CE 221

A high-performance material with excellent strength, rigidity and temperature resistance (231°C)

UMA 90

Single cure resin with enhanced toughness, appropriate for use in prototypes, jigs and fixtures.

RPU 130

Strong, tough, and heat resistant. With a move towards sustainability, 30% of RPU 130’s composition comes from plant-based sources.

Multi Jet Fusion

HP Multi Jet Fusion 5200 – 1 Printer

Lead time: 1 – 4 days

Build platform (mm): 380 x 284 x 380

Accuracy: to ± 0.3%

Print resolution: 1200 dpi

Wall thickness: 0.08 mm

Surface structure: Smooth and uniform with no support structures.

MJF parts are robust and suitable for end-use. Our post-processing includes PolyShot Surfacing to achieve a satin finish, and dye options in 170 colours.

HP Multi Jet Fusion 4200 – 1 Printer

Lead time: 1 – 4 days

Build platform (mm): 380 x 284 x 380

Accuracy: to ± 0.3%

Print resolution: 1200 dpi

Wall thickness: 0.08 mm

Surface structure: Smooth and uniform with no support structures.

MJF parts are robust and suitable for end-use. Our post-processing includes PolyShot Surfacing to achieve a satin finish, and dye options in 170 colours.

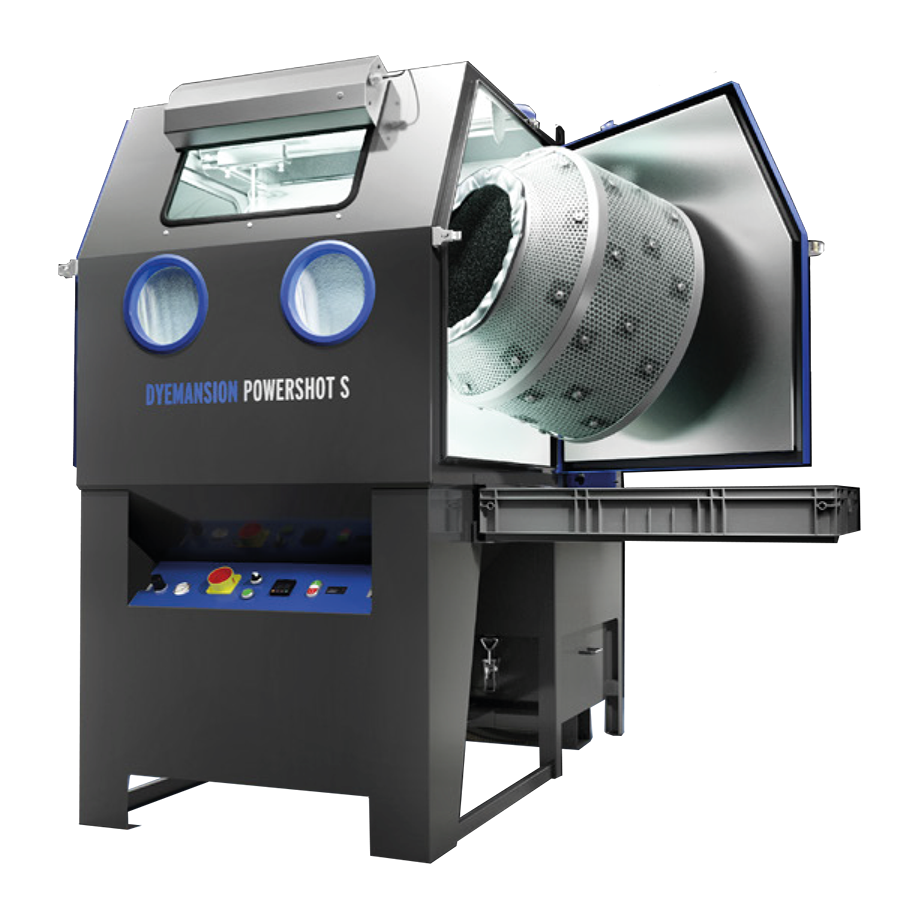

POLYSHOT SURFACING

DYEMANSION POWERSHOT S

Lead time: 4 days

Surface structure: PolyShot Surfacing (PSS) is an efficient process to achieve excellent end-use part finishes. No materials are removed, and the process is effective across all geometries. Cycle times are short, and capacity is substantial, enabling cost efficiencies to be passed on to the customer.

Most effective on PA11 and PA12 Nylons.

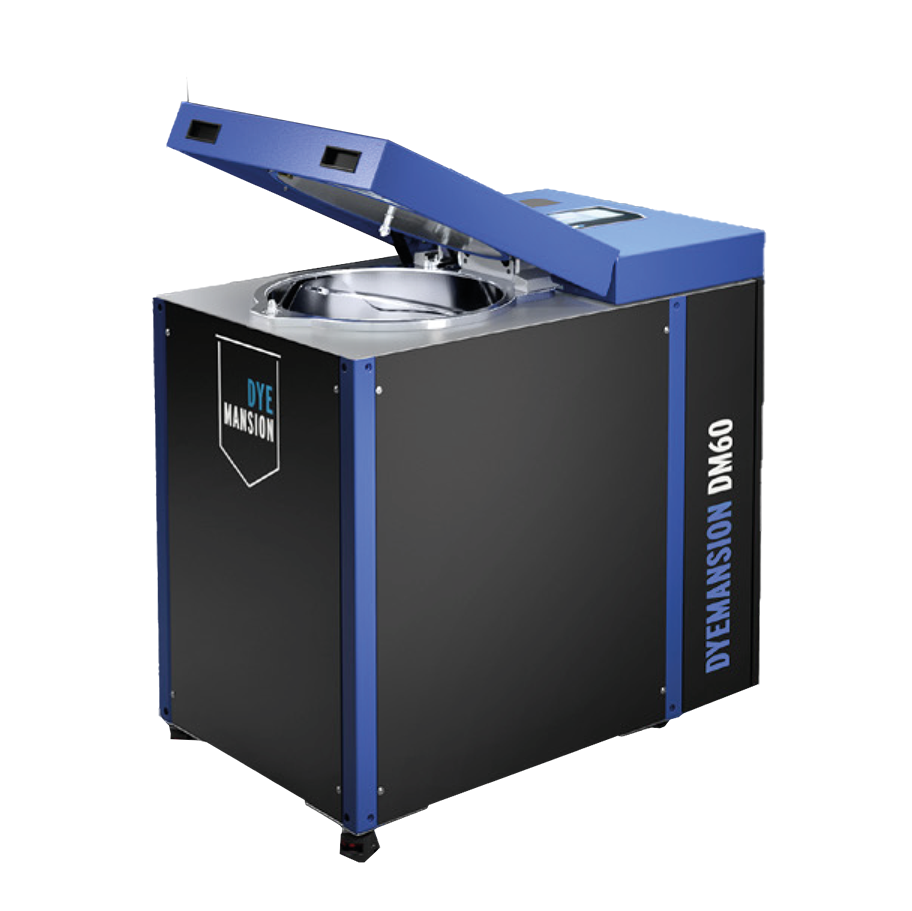

DYEMANSION POWERSHOT C

Lead time: 4 days

Surface structure: PolyShot Surfacing (PSS) is an efficient process to achieve excellent end-use part finishes. No materials are removed, and the process is effective across all geometries. Cycle times are short, and capacity is substantial, enabling cost efficiencies to be passed on to the customer.

Most effective on PA11 and PA12 Nylons.