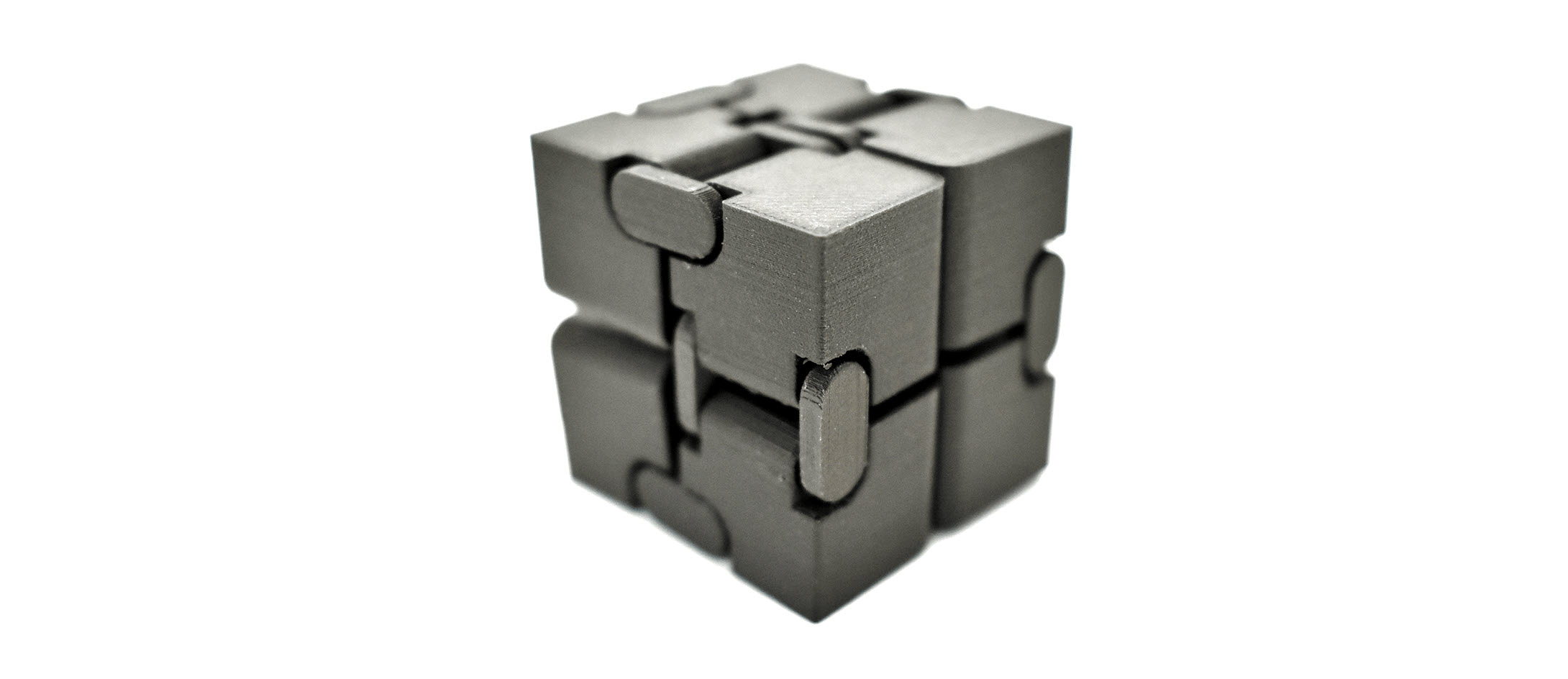

FUSED FILAMENT FABRICATION 3D PRINTING

Why FFF?

FFF or composite 3D printing utilises an extrusion process and highly durable, production-grade thermoplastic resins. FFF delivers parts with mechanical stability, high heat resistance, and in some instances, excellent flammability scores. The FFF material ‘Onyx’ can be combined with a variety of materials, making the results some of the strongest 3D printed parts around.

FFF is suitable for one-off functional prototypes, hard-wearing tooling, and low volume functional parts. Parts are ready for use straight off the printer.