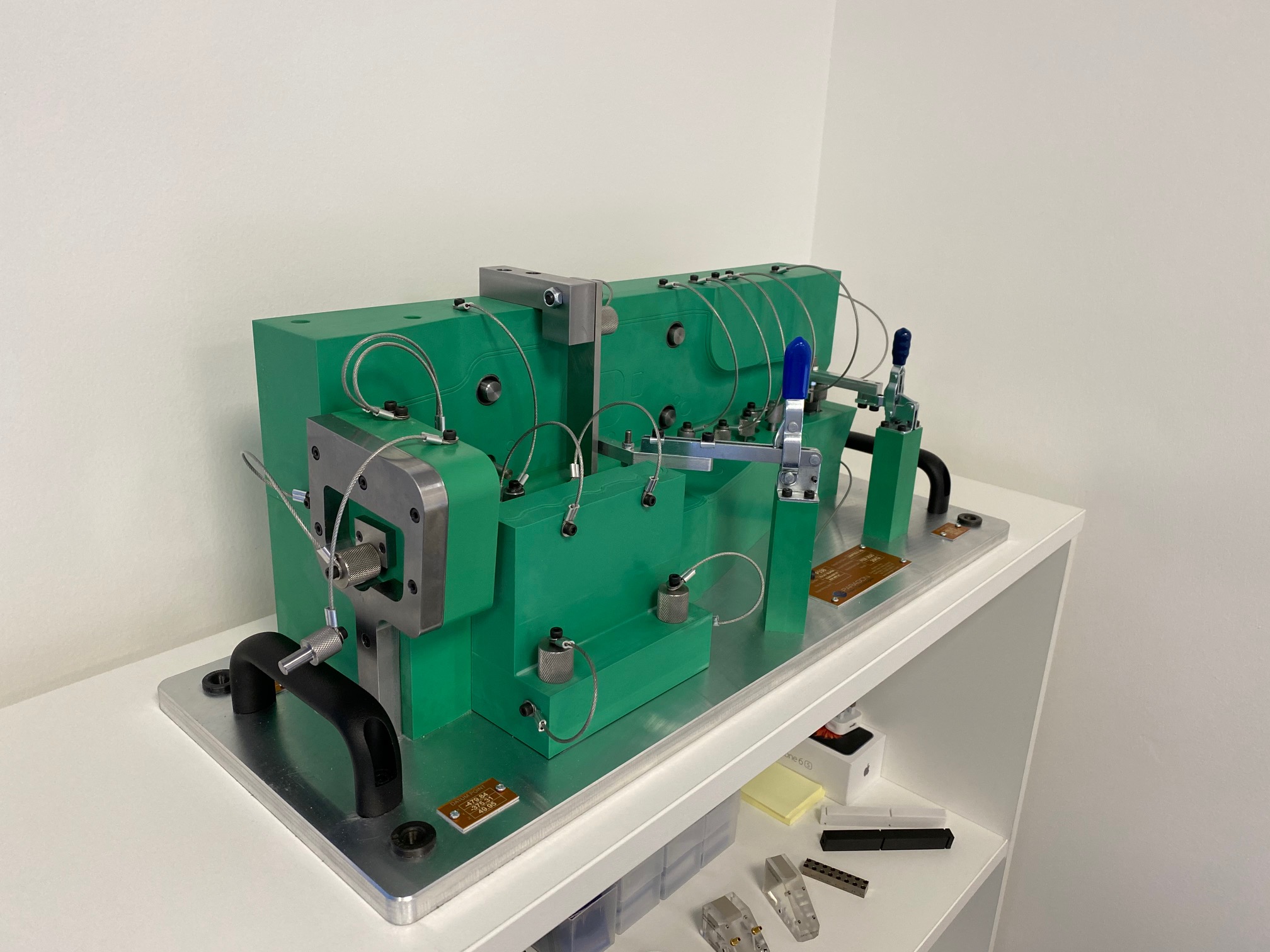

High Tolerance Gauge, Jigs and Fixtures

In-house design and assembly

We manufacture gauges, jigs and fixtures to bespoke designs. By machining various materials, including aluminium and high-density model board, each element of the gauge is manufactured to the customer’s requirements by our expert machinists. The gauge then goes through its preliminary assembly prior to being inspected.

Manufacturing

All gauges are inspected to a tolerance of 0.05mm across key elements of the checking form. This inspection is carried out by our qualified inspectors using our FAROARM technology. Upon internal approvals our gauges then receive their reference plaques, establishing their datum points. We also provide 100% inspection reports.

Inspection and Verification

Upon receiving a quotation, our design engineers work hand in hand with our clients to establish the gauge purpose from the final part data. Working within stringent quality standards and tolerances a concept is then finalised by our design engineers and approved by our customer prior to manufacture.