VACUUM CASTING, RIM, SILICONE CASTING, MODEL SHOP

Rapid prototyping and low volume manufacturing. Form, functionality and fabrication.

As fast as the manufacturing landscape may be changing, there is still a need for conventional, tried and tested prototyping, model-making and low volume manufacturing methods. Especially when it comes to large parts and complex materials. Wherever you are in the product development life cycle, we believe the validation prototypes, functionality testing parts, complex concept visualisation displays and low volume manufacturing solutions you need should be cost-effective without compromising quality. Rapid technologies are, as the name suggests, a quick way to achieve this.

Our mission is to help you design better, reduce costs and streamline production. Even though rapid technologies are considered ‘traditional’, we invest in the best technologies to deliver the best solutions to your manufacturing challenges. We collaborate with you at each stage of your product journey, from materials research to design iterations. We combine traditional technologies with the latest digital manufacturing methods. We do our best to ensure outcomes are best for you and your customers, and they are delivered with exceptional levels of support and service.

3D printing enables faster innovation. The 3D revolution and digitalisation of the manufacturing industry is driving radical changes in production process. Today’s manufacturing focus is all about driving down costs.

With speed, quality, and an ability to reproduce complex geometries time and again, 3D printing is key to this innovation revolution. Our array of 3D printing services enable you to develop customized parts and model components.

READ MORE>>

Vacuum casting

When your brief is for pre-launch testing, low volume manufacture of simple parts or concept models and prototypes, you want a reliable, cost-effective alternative to injection moulding. Vacuum casting fits that bill.

Tooling is fast and economical. The resultant parts are high-quality, and their attributes are comparable to injection-moulded parts and can be formed with very tight tolerances.

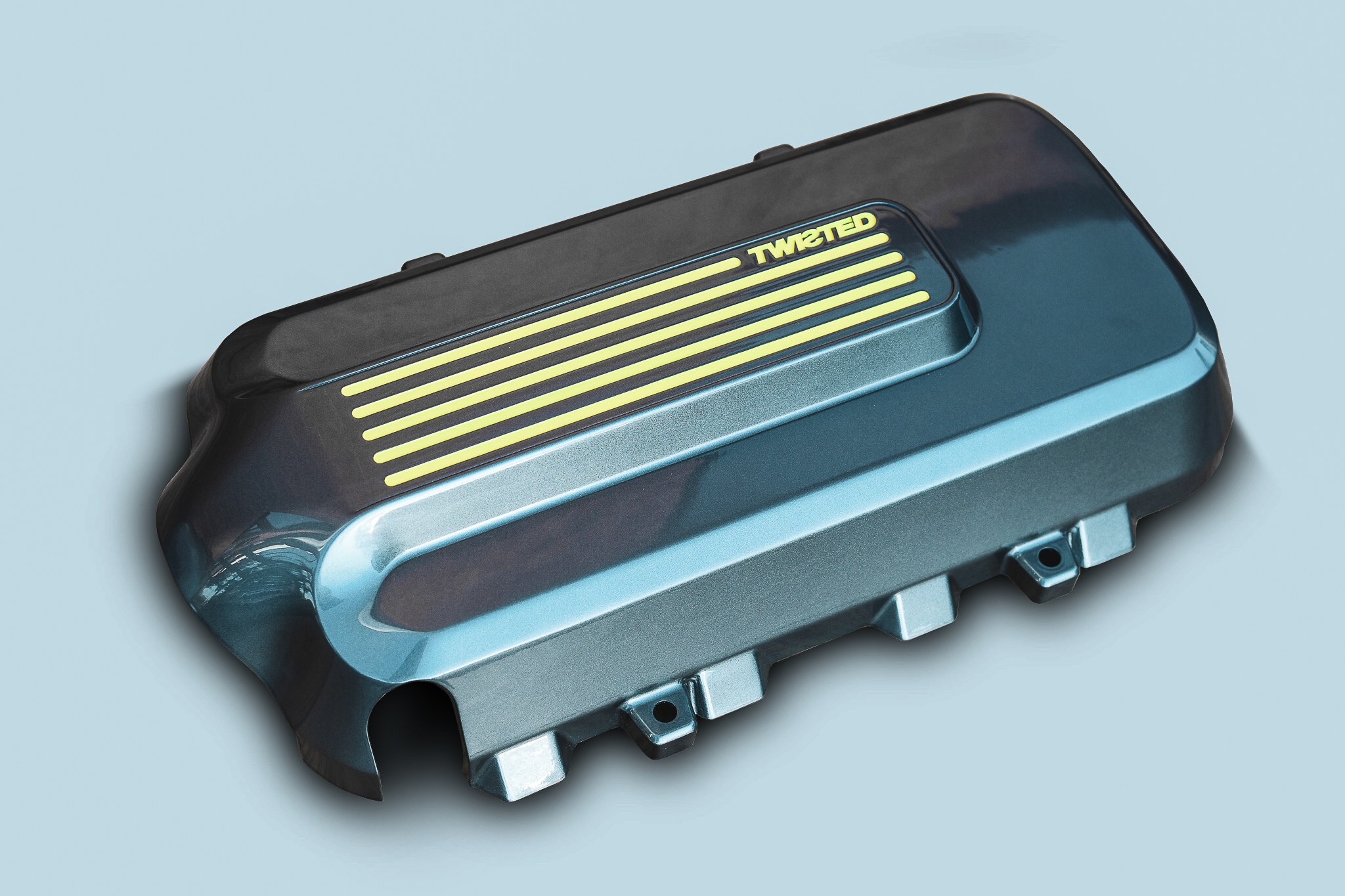

When you need medium to large, durable, flexible (or rigid), lightweight parts with thin walls and intricate detailing, reaction injection moulding (RIM) provides a flexible and cost-efficient solution.

Unlike the more conventional thermoplastic process of injection moulding, RIM allows for fine detailing in design to be accommodated, as can over-moulding.

With its excellent thermal, electrical and chemical resistance properties, silicone rubber is ideal for a wide variety of applications, from keypads to prostheses covers, from hand grips to motor sports components.

Creating silicone components for your products is quick, and cost-efficient.

Make an impact on your customers with superbly crafted, functional, geometrically precise replicas of your products and concepts.

From static display models to fully working miniatures, there’s little our expert team of modelmakers can’t achieve.