Case Studies: Using HP MJF Additive Manufacturing in Automotive Engineering

The use of MJF in automotive applications with HP and Production Partners

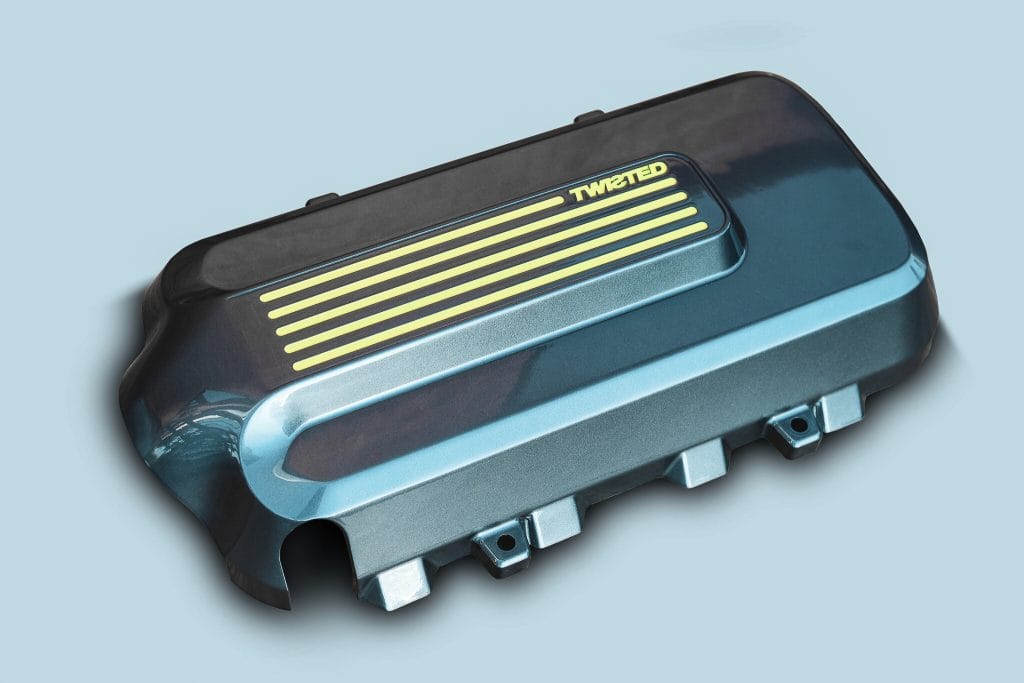

Case Study: Twisted saves time and money with vacuum cast engine covers

Engine re-mapping and redesign to deliver increased horse power are the cornerstones of Twisted’s reconstruction of the iconic Land Rover Defender. As a

result of this increased capacity, the engine covers required remodelling to accommodate additional components.

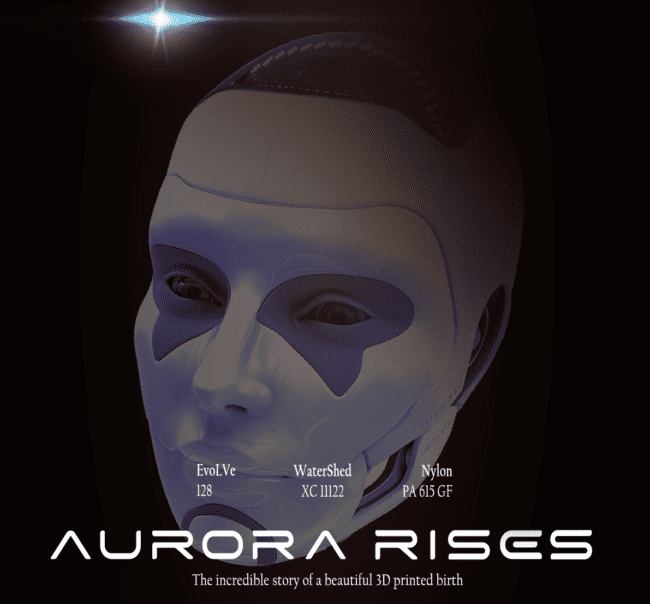

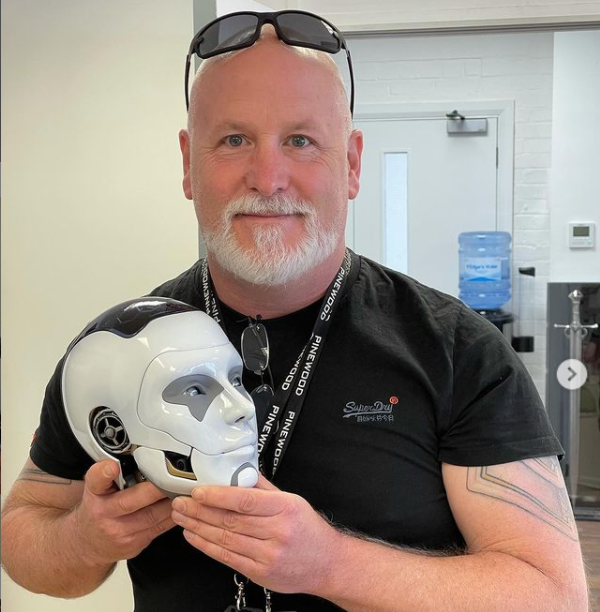

Aurora Rises Episode 4 The Final Cut – How to get a head in model making

Aurora’s journey, documented as a series of episodes for social media, started back in April of 2021 as a series of 3D drawings. Aurora’s stunning completion is down to two of Paragon’s expert modelmakers, Lee Adams and Tristan Brown.

Contract Management of Component Parts Manufacture: Automotive

Contract Management for Automotive: To supply 250 car sets of components in accordance with our customer’s build schedule

Aurora Rises Episode 3 – Originator of Species

An interview with Jet Cooper, Creative Director and Head of 3D at Makinarium UK Ltd. Aurora is the brainchild of Jet Cooper, designed to demonstrate the versatility of 3D printing to the film industry.

The TiMbandAir Baby Helmet

Invent Medical combines custom software with Multi Jet Fusion 3D Printing and Post-Processing Solutions to produce personalised, economical cranial remoulding helmets for babies.

DLS: Agrifac Nozzle

From selling sprayers to farmers around the small Dutch city of Steenwijk, to a global mission to help to feed the world with safe, sufficient and nutritious food without increasing the need for chemicals, Agrifac has come a long way in 80 years.

Telemedic Systems Ltd Vitalink3

Octo Design Limited developed a product specification for the complex, challenging twin shot design. Paragon was chosen to produce the prototypes because of their proven history of producing rapid prototypes of 2-shot designs and their existing relationship with Octo Design.

I-Limb Skin

Paragon Rapid Technologies worked with Touch Bionics of Edinburgh with the development of their i-LIMB Hand. This is a first-to-market prosthetic device with five individually powered digits.

Blatchford Cover

Blatchford, a global leader in mobility solutions focussing on breakthrough technologies and services, have been manufacturing prosthetics and orthotics for over 129 years.