3D PRINTING TECHNOLOGIES

SLS Materials

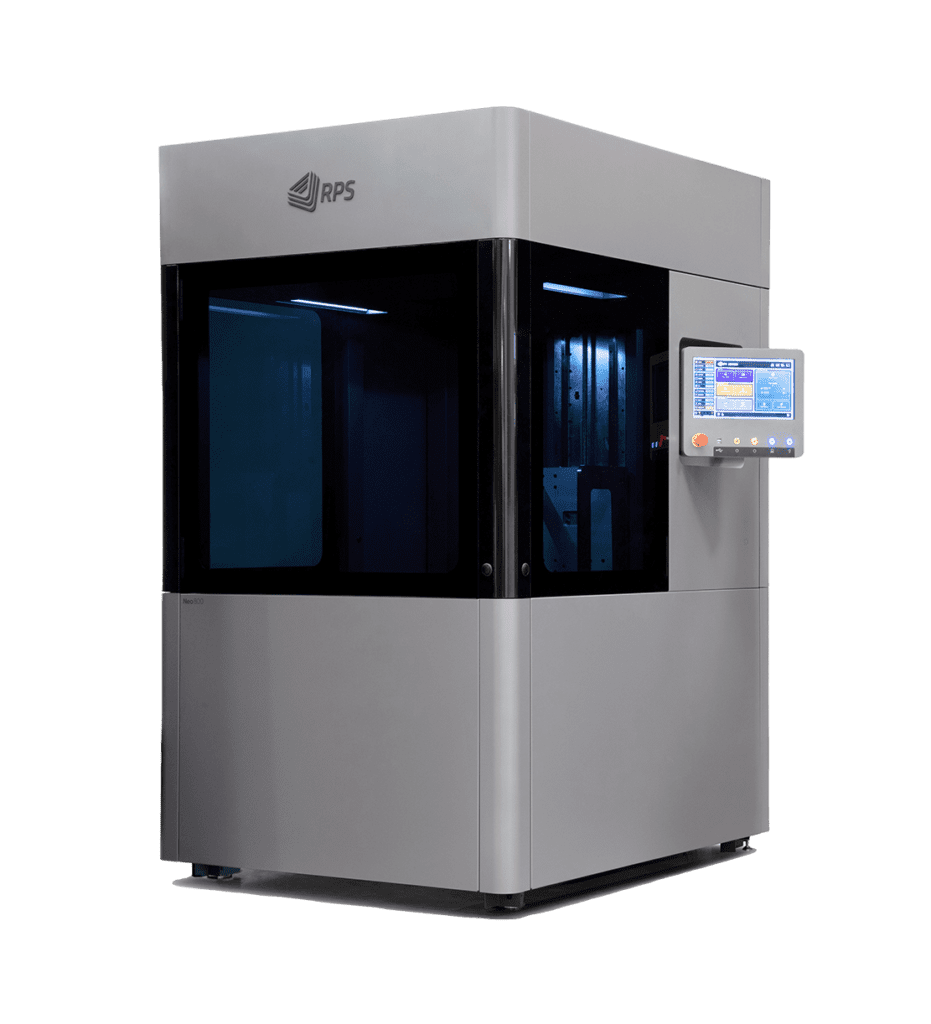

SL TECHNOLOGY

NEO 800 – 3 Machines

Lead time: 1 – 4 days

Build platform (mm): 800 x 800 x 600

Accuracy: to ± 0.15%*

Layer resolution: 100 µm

Wall thickness: 0.5 mm*

Surface structure: Requires support structures

Thanks to the NEO800’s exceptional scanning repeatability, sidewall quality and dynamic laser processing, very little A-surface finishing is required. Parts can be painted and coated.

*Geometry and part size-dependent

SL Materials

FFF Materials

Vacuum Casting Technologies

Vacuum Casting Materials

Clear PC

Clear polycarbonate with high UV stability, suitable for prototyping optical lenses. Can be coated and coloured.

GF Nylon

High flexural modulus of elasticity. Filled with milled glass fibre. Can be easily coloured.

UL94 V0

A rigid, superior strength white resin with excellent impact resistance. Can be coloured. Certified fire retardant: UL94 V-0.

Elastomer

Shore A50 rubber to Shore A85 rubber. Perfect for casting decorative objects, production parts, tools, models, patterns, duplicate masters and more. Can be pigmented or dyed.

Clear Elastomer

Water white clear urethane liquid rubber compounds for applications requiring absolute clarity and resistance to sunlight. Shore 50A and Shore 95A hardness.

ABS

A transparent ABS-like material with excellent all-round functionality and great optical properties. Suitable for snap fits, low temperature applications and colour matching.

Reaction Injection Moulding Technologies

RIM Materials

High Temp PP

Polypropylene simulant for high temperature applications, such as under the bonnet uses in the automotive industry. Available in neutral or black.

GF Reinforced

Glass fibre re-enforced polyurethane resin. Ideal for functional, cladding and prototyping applications.

PP

Semi-rigid polyurethane in black or beige. Suitable for high impact applications including, electrical, furniture and automotive.

Silicone Materials

Dragon Skin

Strong and stretchy, high-performance, white-translucent silicone rubbers. Used to cast silicone parts in the entertainments sector, e.g. for special effects and skins for animatronics; in the medical sector for orthopaedic cushioning, prosthetics and robotics; and for prototyping.