ADDITIVE MANUFACTURING (3D PRINTING FOR PRODUCTION) WITH HP MULTI JET FUSION (MJF)

Why HP Multi Jet Fusion?

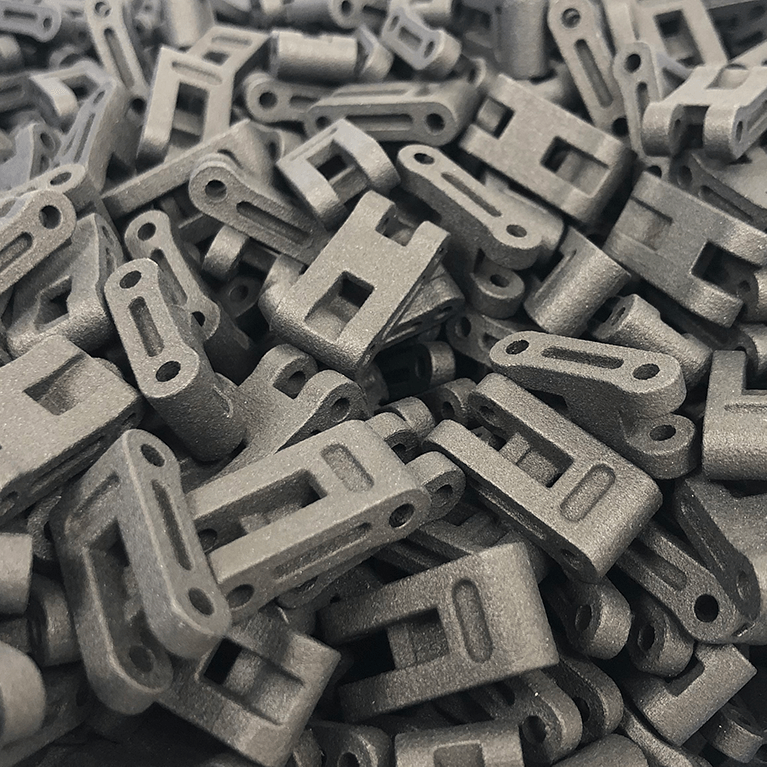

HP Multi Jet Fusion (MJF) is a relatively new powder-based additive manufacturing process for producing high-resolution, low porosity and high surface quality end-use objects at volume.

HP Multi Jet Fusion (MJF) is a relatively new powder-based additive manufacturing process for producing high-resolution, low porosity and high surface quality end-use objects at volume.

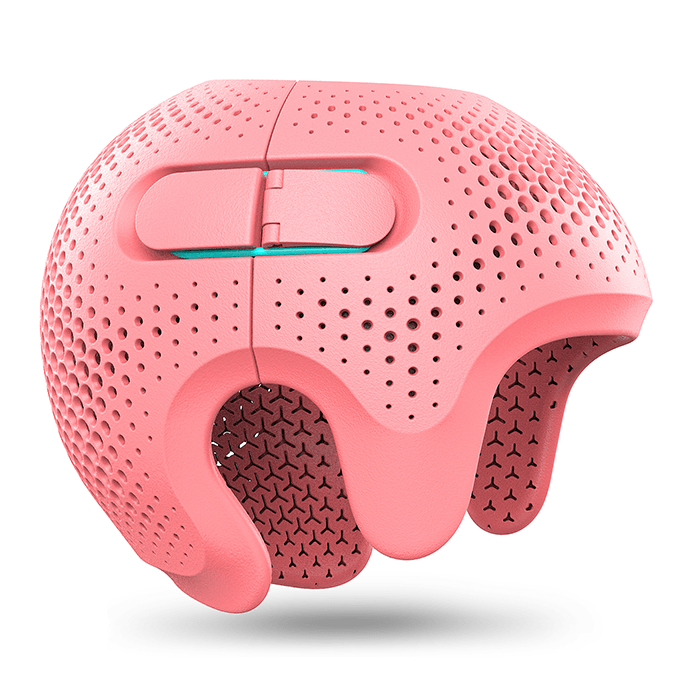

Approximately three times faster than some traditional SLS technologies, MJF uses infrared as a binding source. The resultant product is smooth and uniform with little layering. Mechanical properties are in many ways superior to SLS-produced prints. MJF also addresses the sustainability issue through re-usability.

Our HP MJF printing is supported by state-of-the-art post processing facilities, paving the way for seamless and rapid production. The DyeMansion suite enables us to deliver satin smooth, dyed parts ready for wear or direct application.