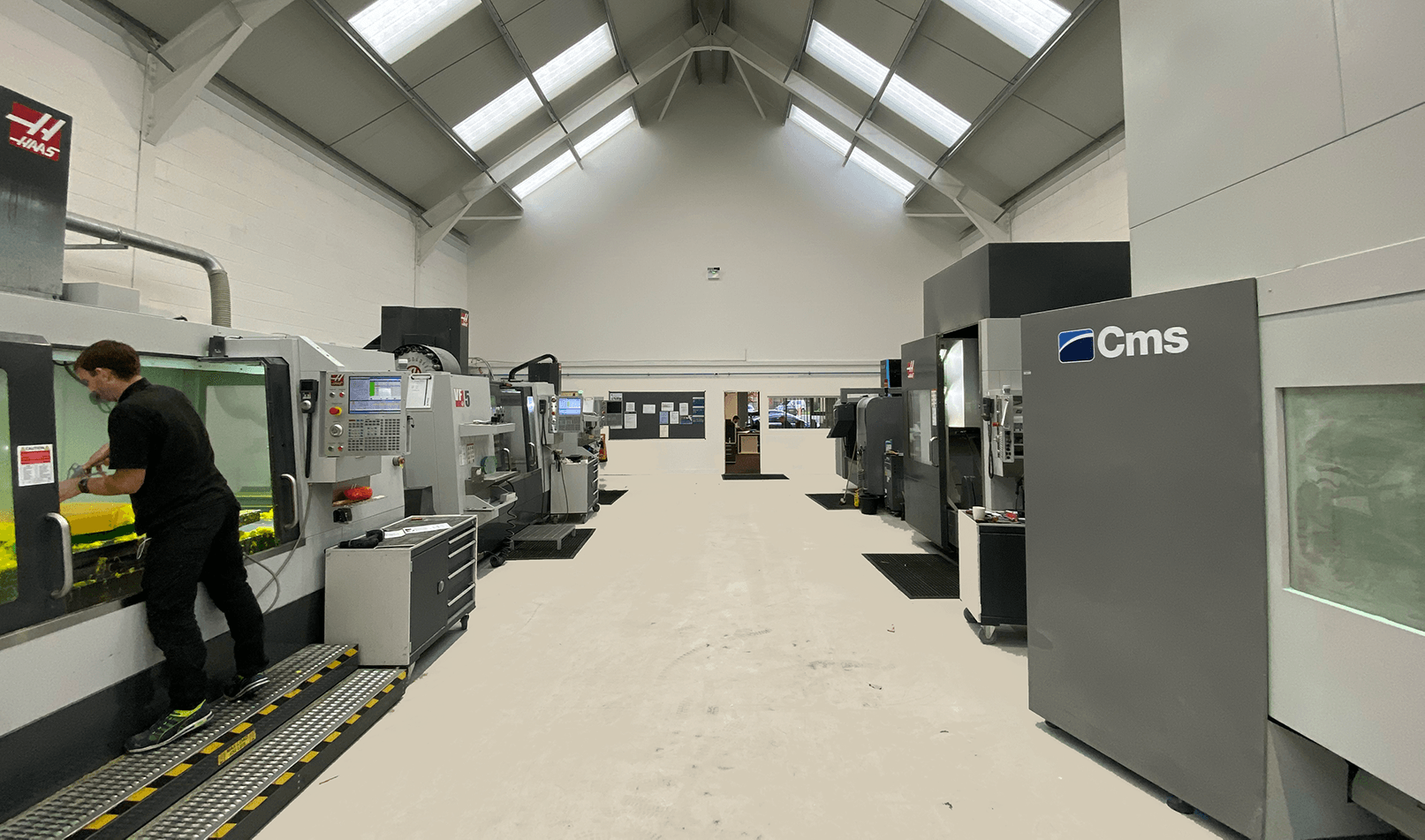

CNC

Redefine your supply chain with increased efficiency and productivity through quality assured CNC milling and turning

Companies have never been under so much pressure to innovate faster. If you are to succeed, you need your product to be in front of its target audience as quickly as possible. At the same time, you’re expected to meet progressively tougher design and production challenges without incurring greater costs. We have an array of CNC machining services enabling fast turnaround of end parts and prototypes.

Our CNC milling and turning services deliver on competitively priced support for manufacturing with precision parts and products in a variety of engineering-grade materials. To assist with quality control in high volume production, we offer a bespoke jigs, fixtures and gauges design and manufacturing service. We can also help you meet those progressively tougher design and production challenges in isolation or in collaboration with our Additive Manufacturing and Prototyping capabilities.

We have been providing quality, precision CNC engineering solutions to our customers since 2003. Our outstanding technical expertise and process knowledge help us provide manufacturing support of the highest quality. When you’re ready to start production, we have the tooling and moulding capability and expertise to ensure your runs are perfect, every time.

Machining & Turning

We have a wide range of materials to help you meet the most challenging engineering problems. Our 5 axis capabilities enable engineering in steel, aluminium, all rigid plastics, EPP and composite boards.

Our 5-axis capability enables post-machining of production models; low volume manufacturing of metal machined components; and the creation of styling models, gauges, jigs, fixtures and compression tooling up to 2500 x 1500 x 1200 mm.

Our 3-axis capability enables milling and cutting of steel, aluminium, ABS, model board, foam, and nylon. Customers benefit from competitively priced, exceptional quality, low volume metal machined components, in addition to styling models, gauges, jigs, fixtures and compression tooling up to 1626 x 813 x 762 mm.

Gauges, Jigs & Fixtures

We know that when it comes to manufacturing, you’re under pressure to keep costs down and quality levels consistently high.

Our CNC technologies and expert design engineers enable us to create the gauges, jigs and fixtures that are essential to your company productivity and quality control levels. Our engineers adhere to stringent quality standards to ensure your complete confidence in achieving durable, stable and repeatable parts. We use the latest FAROArm technology for full validation reporting against original parts. And, we make sure our own manufacturing process includes short lead-times, competitive pricing and unrivalled levels of customer service.

Component parts

Our state-of-the-art CNC technology enables you to create new or customised parts with complex geometries quickly and economically.

Our CNC Technologies business is underscored by an ethos of collaboration and contract management. We work with you to identify and validate the most appropriate materials and machining methods, enabling you start production with guaranteed reduced turnaround times, extreme precision and unfailing endurance, and a guarantee of quality for every batch.

With years of experience, an unrivalled commitment to quality and an exceptionally responsive engineering team on your side, we’re ready to help you through the entire production process.

Tooling, Moulds and Dies

Tooling is an essential part of the product development cycle, and crucial to the manufacturing process. The speed to market, quality, repeatability and accuracy of your component, prototype, or finished product will depend on the precision and characteristics of your tooling.

We can help you save on labour and quality costs and improve on delivery speeds. We offer a comprehensive range of tooling solutions for the modern manufacturing environment. Our large-gantry, state-of-the-art 3-, 4- and 5-axis CNC machines provide facility for the creation of assembly tools, RIM tools, press tools, and specialist dies and moulds.

Inspection

We offer quality inspection and specified rework services.

Using FAROArm Edge technology to UKAS national standards, every gauge, jig, fixture, tool and part is measured for accuracy and assurance before it leaves our factory. Large as well as small parts can be accommodated. This gives us, and you, the power to control and assure quality at each stage of the manufacturing and supply process.