Paragon Rapid Technologies – Quality Policy

Paragon Rapid Technologies – Quality Policy 5.1

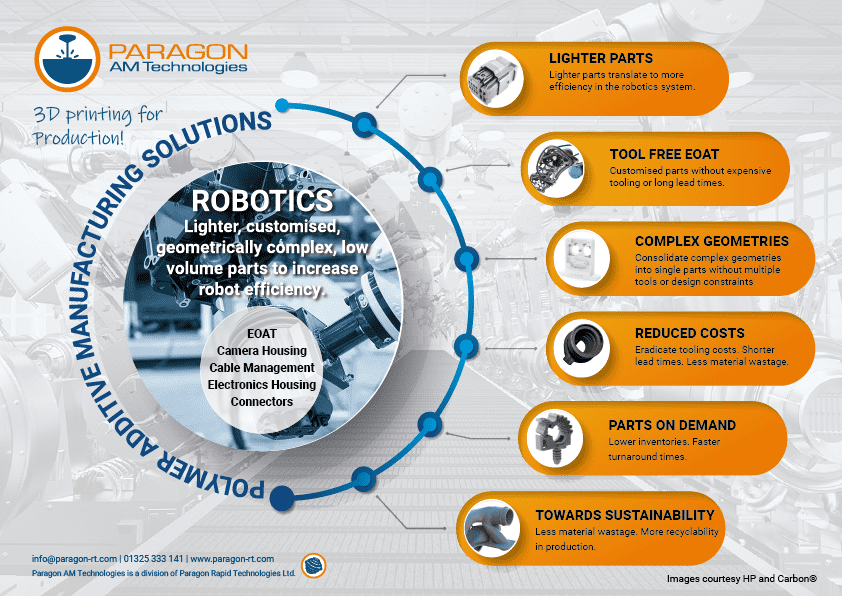

Infographic: Polymer AM for Robotics

This infographic highlights the benefits of polymer AM for applications in the robotics industry.

Reaction Injection Moulding (RIM): Beyond Automotive

RIM, or Reaction Injection Moulding, is a low volume manufacturing process used to produce high-strength, lightweight, and complex parts made of polyurethane or other thermosetting polymers. Commonly associated with the automotive industry; but it can be very useful for manufacturing parts for other sectors, too.

Vacuum casting: bringing Industrial Products to market faster and for less

Involving the use of silicone moulds and polyurethane resins, vacuum casting offers several advantages for industrial product manufacturing, including the ability to produce complex and highly detailed parts; a wide range of material options; cost-effectiveness for low-volume production; and relatively short lead times compared to traditional manufacturing methods.

Paragon doubles EvoLVe 128 resin availability

Due to a phenomenal increase in demand from the UK’s TV and film industry, we have doubled our SOMOS EvoLVe 128 availability.

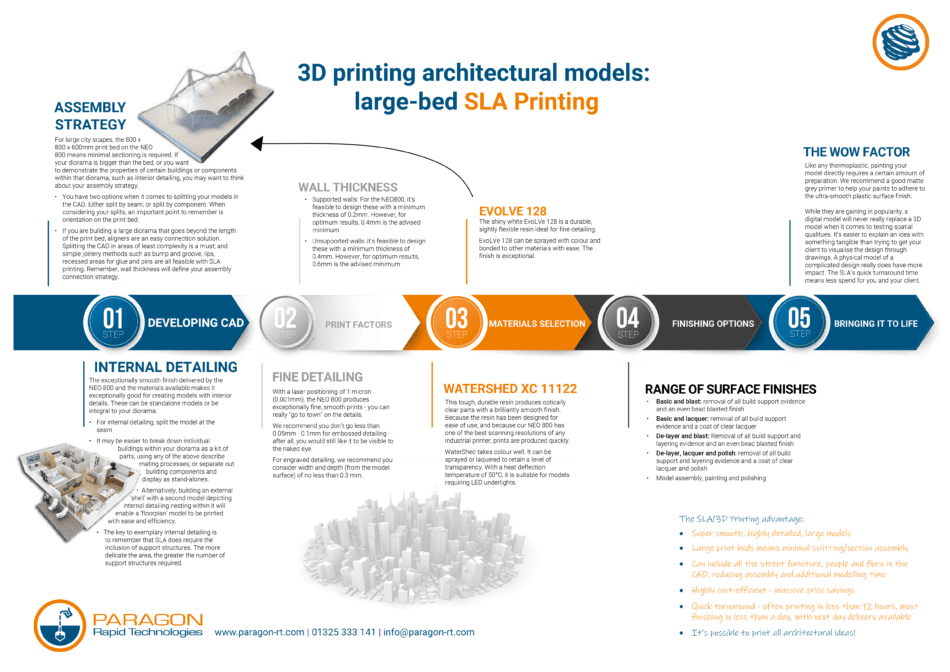

Infographic: Large Bed 3D Printing for Architects

Architectural large bed 3D Printing. For large cityscapes, the 800 x 800 x 600mm print bed on the NEO 800 means minimal sectioning is required.