3D PRINTING WITH STEREOLITHOGRAPHY (SLA)

Why SLA?

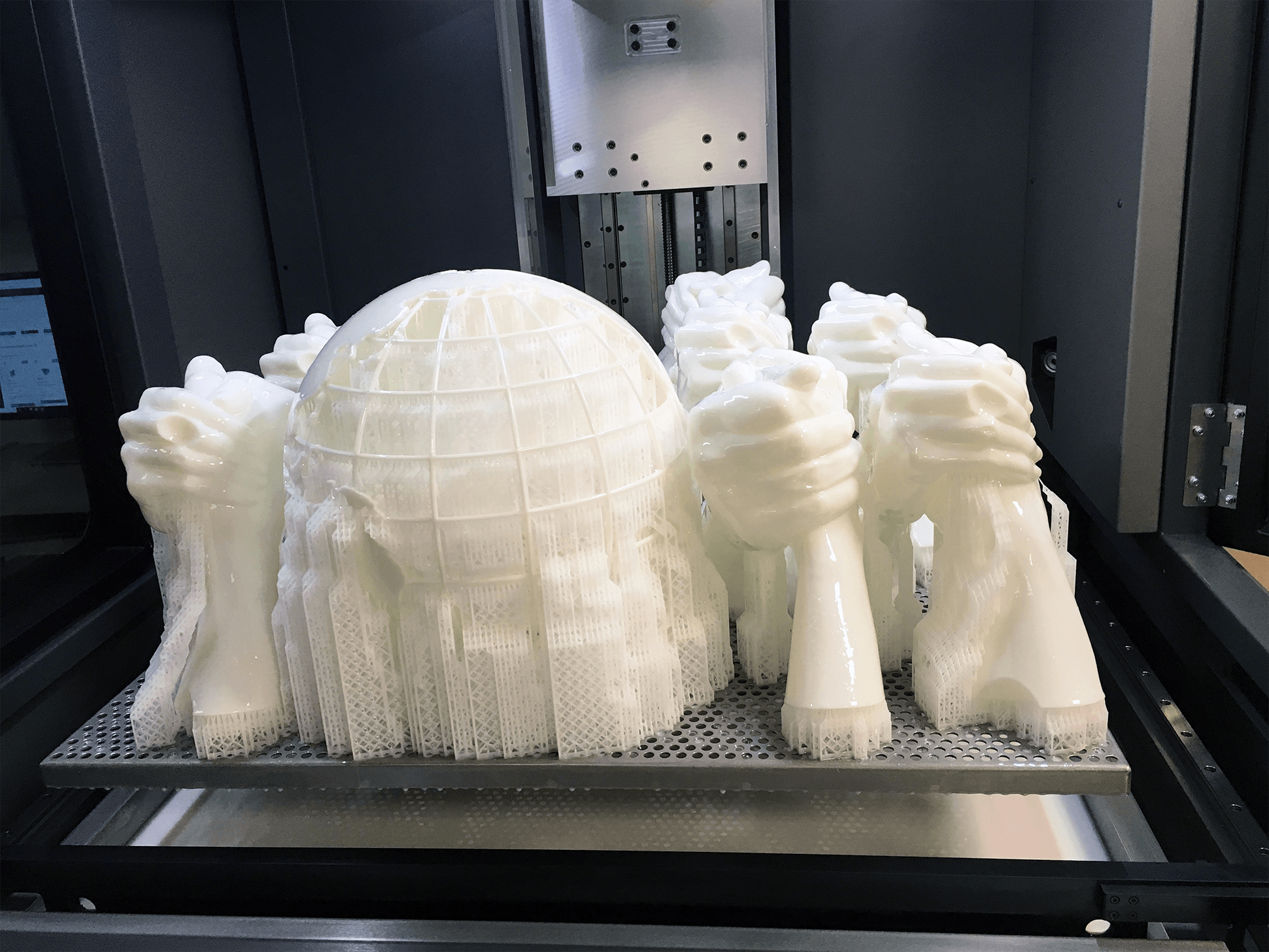

SLA (or stereolithography) is the grandfather of 3D printing. SLA produces exceptional models with outstanding surface quality, offering a look and feel very similar to traditional thermoplastics. Paragon is currently the only 3D printing service provider in the country with three industry-leading, large-bed NEO 800 printers.

This state-of-the-art technology gives you the freedom to print complex designs and fine details in lightweight, robust resins. Thanks to its relatively rapid build time, and the superior quality of the finish straight off the machine, very little post-processing is required. SLA printing is beautifully cost efficient.

Click “Instant Quote” for beautiful parts in as little as 2 days (dependent on your CAD and finishing requirements. UK only).