Build sustainability in the high-turnover world of industrial products innovation

When thinking of industrial products we tend to think of simple designs and work-horse-like functionality. Neverheless, like all other sectors, new digital technologies are constantly transforming the way they are manufactured. From the creation of simple filtration systems to minute parts for production line robots, product development speeds have been greatly enhanced. Production processes are more efficient than ever before. And the race to market has reached a peak of intensity.

We have been helping customers like you transform consumer product development since 2003. Our technologies and materials encourage you to change the way you think about product innovation. They enable you to remove steps in your product development cycle and revolutionise your production processes. They enable you to shrink and flex your supply chain, and enhance the industrial products value chain.

While you need to be flexible and keep costs down for your customers, we can be flexible and keep costs down for you.

Product development support and low volume manufacturing for companies in the industrial products sector including:

- Filtration

- Metrology and instrumentation

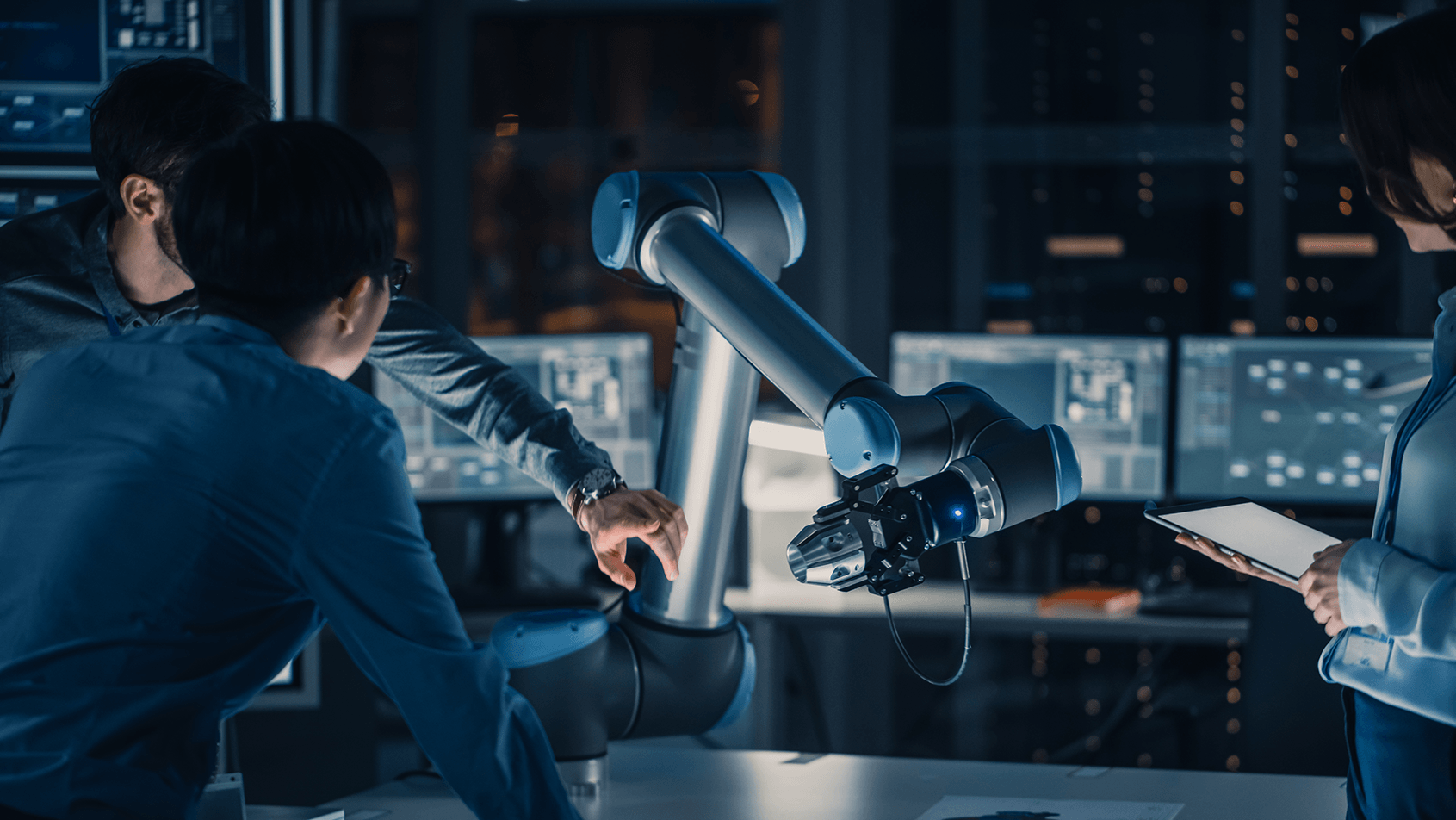

- Robotics and automation

- Industrial furniture

- Lighting

- Communications equipment

- Tooling and construction

- Industrial machinery and equipment

- Electronics

- Hardware

- Wearables and Safety Equipment

- Agricultural machinery and equipment

- Mining and extraction equipment

Additive Manufacturing for Industrial Products

Tool-free solutions for end-use parts

Industrial products need to be tough, robust and durable. Installations, such as industrial machinery, and accessories, such as electrical and robotic components, have to withstand the rigours of both environment and activity. With an array of materials designed to stand up to such rigours, Additive manufacturing gives you the chance to realise your design sooner. It enables you to explore fit and functionality options without incurring tooling costs. And now, with materials specifically designed for production, additive manufacturing can be used to produce end parts without thinking about tooling.

We can help you deliver on value and on economies of scale. Our revolutionary additive manufacturing technologies, Digital Light Synthesis™ and Multi Jet Fusion open up endless exciting production and customisation opportunities. Parts possess all the qualities of injection moulded plastics without the tooling costs. Materials are all biocompatible with resolution.

Rapid Technologies for Industrial Products

Prototypes and low volume solutions for real world applications

Shorten production times for revolutionary ideas and enhance quality with a suite of rapid validation prototyping and testing services, including 3D printing, vacuum casting, reaction injection moulding and silicone casting. Our experienced technicians and model makers deliver highly accurate, production-representative parts produced quickly and cost-effectively using low-cost tooling capabilities.

Read More>>

CNC Technologies for Industrial Products

Lower costs and assure quality with end-to-end supply chain management, and faster tooling and part production times.

Successful industrial product development requires speed to market and accuracy. A supplier who can help you evaluate materials, develop your prototypes, deliver on low volume manufacturing and create production tools quickly and cost-effectively will be a key factor in helping you beat your competition to market.

Our engineering and CNC capabilities allow you to flex your designs, produce prototypes quickly, develop and modify tools for manufacture and achieve outstanding quality at the manufacturing stage. Our cost effective, efficient solutions, including contract manufacturing of component parts, will help you win that race to market, time and time again.