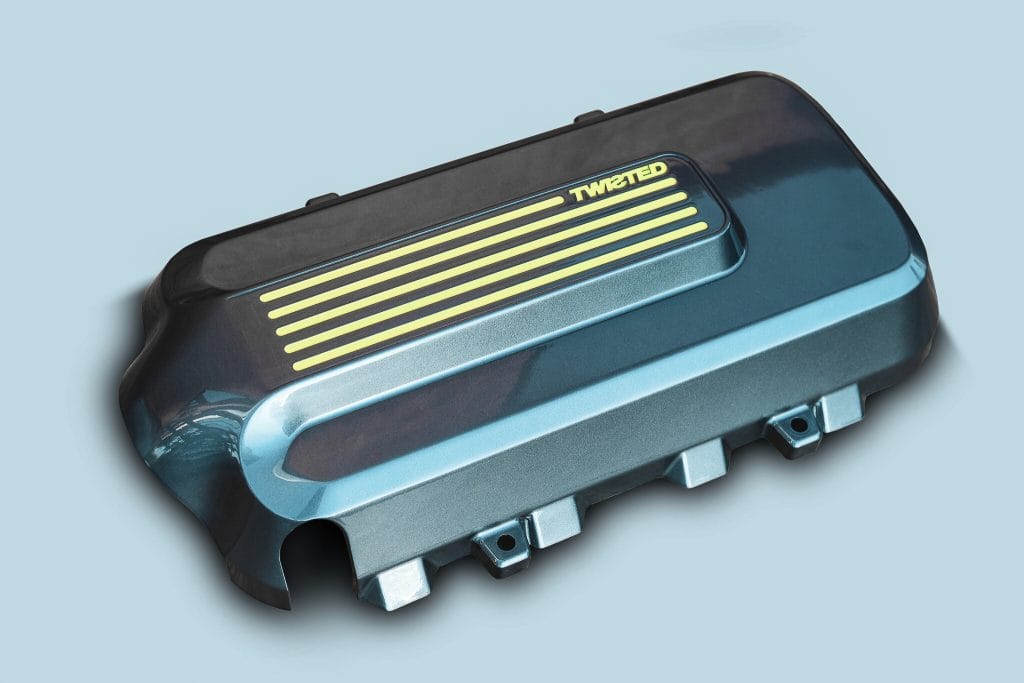

Case Study: Twisted saves time and money with vacuum cast engine covers

Engine re-mapping and redesign to deliver increased horse power are the cornerstones of Twisted’s reconstruction of the iconic Land Rover Defender. As a

result of this increased capacity, the engine covers required remodelling to accommodate additional components.

RIM: a perfect low production run solution for large automotive components

Paragon Rapid Technologies is one of the few companies in the UK offering RIM to automotive companies as an alternative to Injection Moulding for prototyping and low run productions. With CNC facilities on site, we can create model board tools, suitable for 100 or more parts, quickly and efficiently. We are also experts at creating silicone tooling (for up to 80 parts).

Vacuum casting: a perfect low production run solution for automotive engineering

There’s no need to tell automotive design and mechanical engineers just how vacuum casting can be used for prototyping and low-volume production of plastic parts for their vehicles…

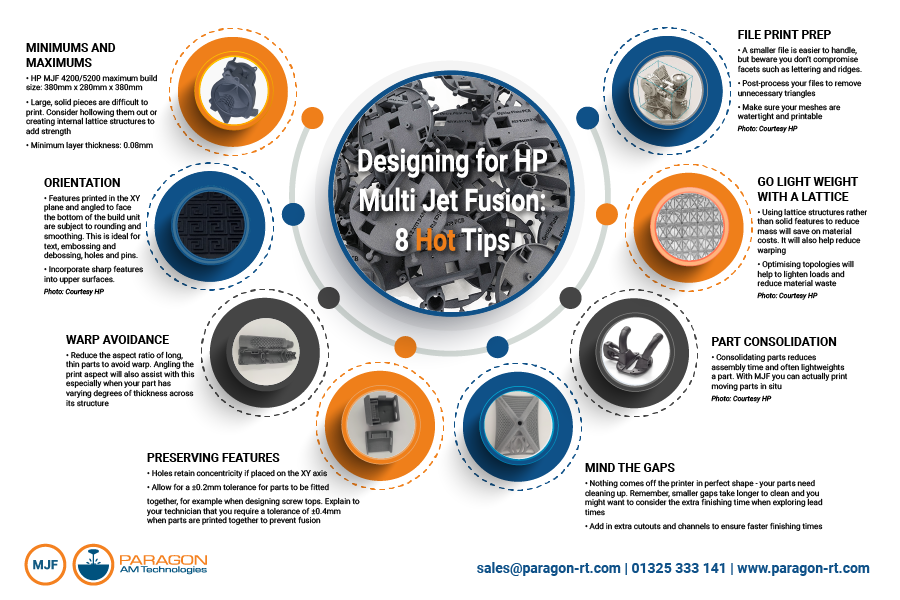

Infographic: Designing for MJF – 8 Hot Tips

Infographic: Getting your MJF 3D Printing for Production designs right first time

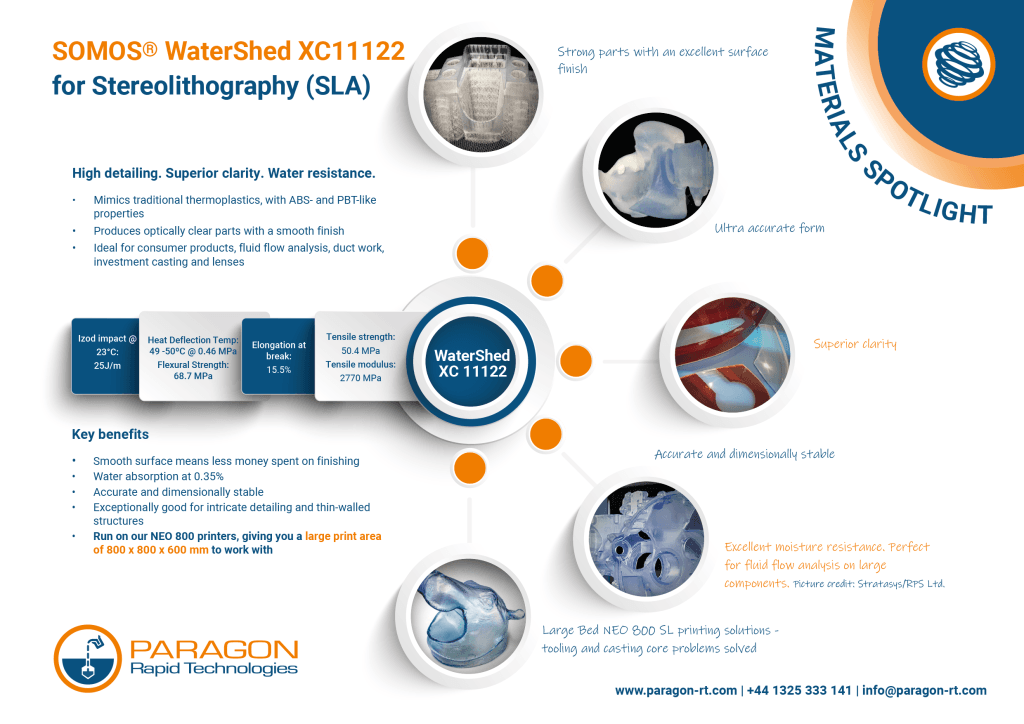

Infographic: Materials Spotlight SOMOS WaterShed XC11122 for SLA Printing

Materials Spotlight: SOMOS WaterShed XC11122 for SLA 3D Printing

Infographic: Materials Spotlight SOMOS EvoLVe for SLA Printing

Materials Spotlight: SOMOS EvoLVe 128 for SLA 3D Printing

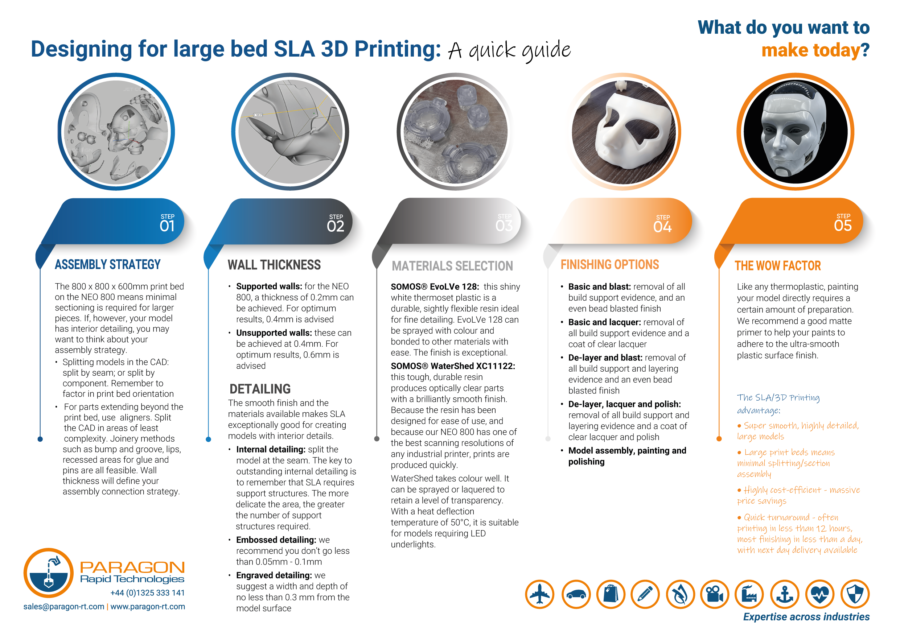

Infographic: Designing for Large Bed SLA 3D Printing – A Quick Guide

This infographic provides some quick reference points for designing for large bed SLA printing

Infographic: SLA vs SLS

This infographic is to help you decide between SLA and SLS printing for prototypes and low volume manufacturing of parts

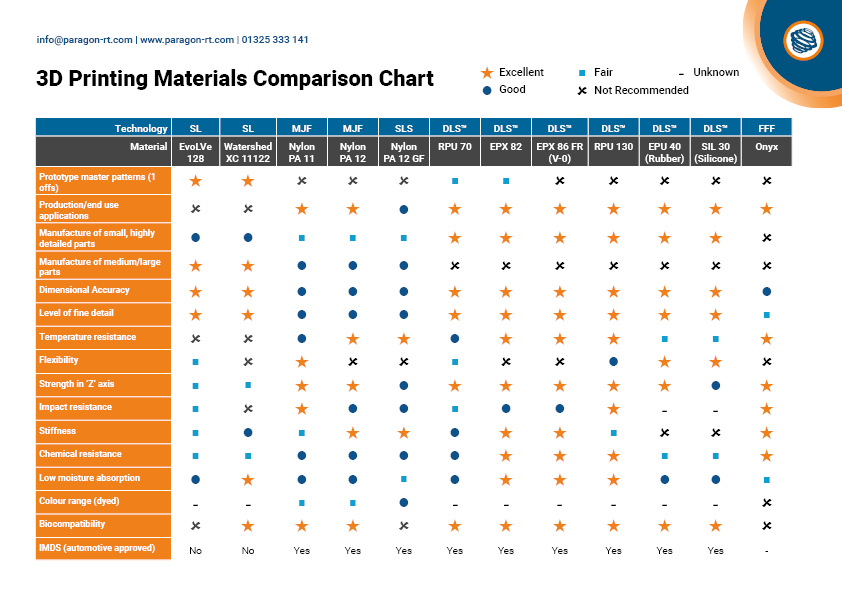

Infographic: 3D Printing Material Comparison Chart

This infographic compares materials used in 3D printing and polymer additive manufacturing.

Infographic: Materials Spotlight EPX 86FR for DLS

This infographic highlights the benefits of new resin, EPX 86 FR for DLS additive manufacturing