The Apprentice Paragon Edition – Megan Thomas, You’re Hired!

My name is Megan and I am proud to have successfully completed an apprenticeship in Engineering Operations at Paragon Rapid Technologies. The apprenticeship was conducted in collaboration with City and Guilds through Middlesbrough College.

Vacuum casting: bringing Industrial Products to market faster and for less

Involving the use of silicone moulds and polyurethane resins, vacuum casting offers several advantages for industrial product manufacturing, including the ability to produce complex and highly detailed parts; a wide range of material options; cost-effectiveness for low-volume production; and relatively short lead times compared to traditional manufacturing methods.

Polymer Additive Manufacturing: Driving Robotic Innovation

Now that additive manufacturing polymers are being created for real world applications, issues such as temperature resistance, tolerances and robustness are no longer concerns. Polymer parts are lighter, making the robot more energy efficient and cheaper to run.

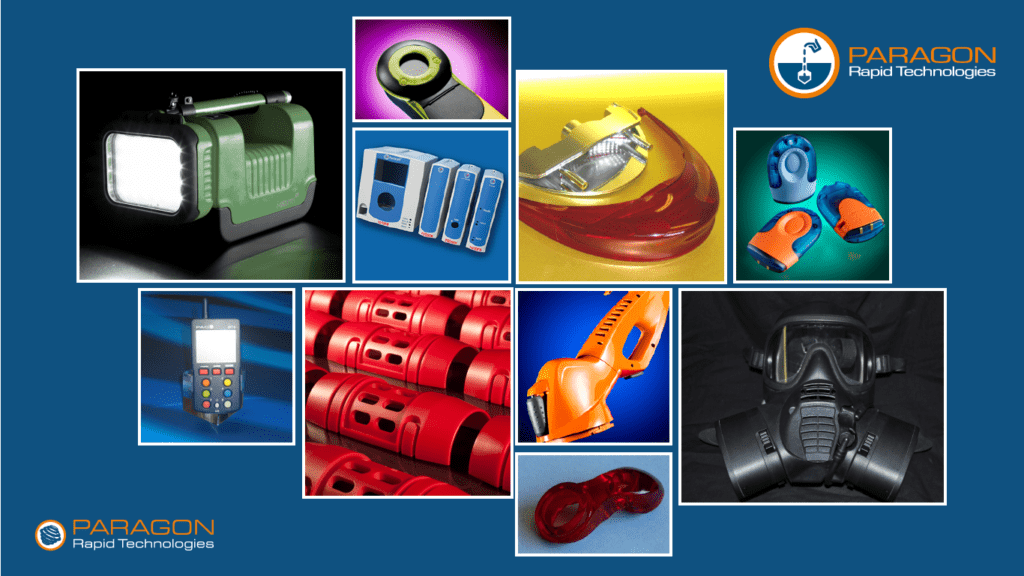

Solving Manufacturing and Engineering Problems – An Unbiased Approach

Following a manufacturing technology and process-agnostic approach means that, as an engineering and manufacturing business, we are unbiased towards the use of any specific technologies to solve your manufacturing problems.

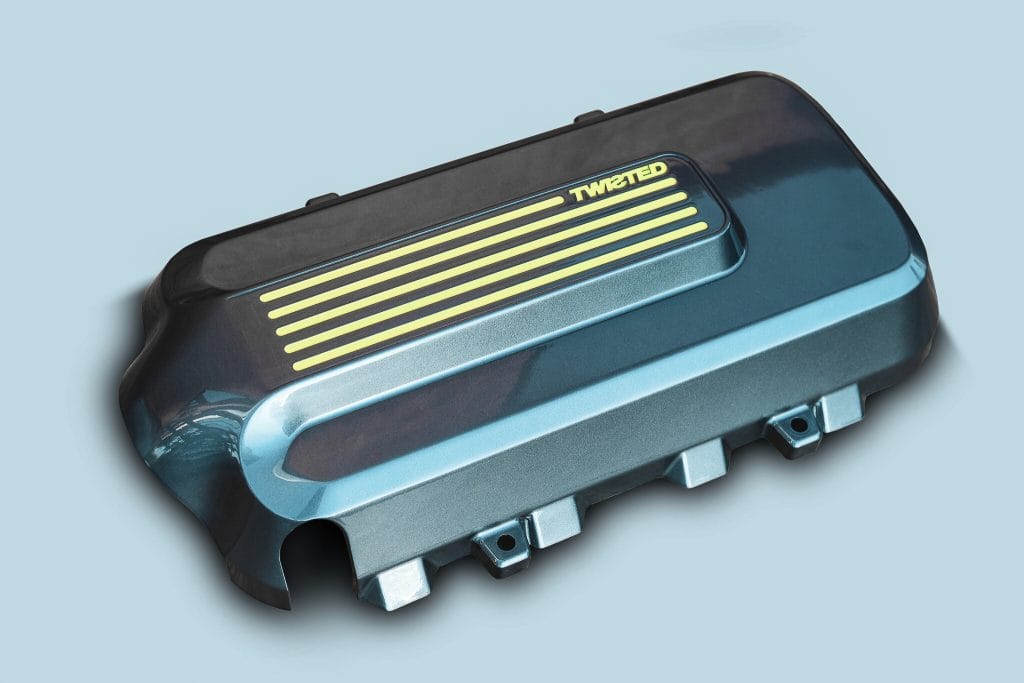

Case Study: Twisted saves time and money with vacuum cast engine covers

Engine re-mapping and redesign to deliver increased horse power are the cornerstones of Twisted’s reconstruction of the iconic Land Rover Defender. As a

result of this increased capacity, the engine covers required remodelling to accommodate additional components.

RIM: a perfect low production run solution for large automotive components

Paragon Rapid Technologies is one of the few companies in the UK offering RIM to automotive companies as an alternative to Injection Moulding for prototyping and low run productions. With CNC facilities on site, we can create model board tools, suitable for 100 or more parts, quickly and efficiently. We are also experts at creating silicone tooling (for up to 80 parts).

Vacuum casting: a perfect low production run solution for automotive engineering

There’s no need to tell automotive design and mechanical engineers just how vacuum casting can be used for prototyping and low-volume production of plastic parts for their vehicles…

Additive Manufacturing: The Lattice Advantage

Currently, the lattice structures that offer the solutions to thermoregulation, bulk and those fatigue issues can only really be produced through 3D printing. But additive manufacturing means so much more, from customisation to impact optimisation.

HP Multi Jet Fusion (MJF) Applications in the Automotive Industry

Multi Jet Fusion Applications in Automotive Engineering

Prototyping to production: beyond design validation with 3D Printing

The cost of additive manufacturing (AM) reduces daily. By eradicating the tooling component, production cycles are truncated and more cost effective. Roadblocks are reducing. What do you need to do to drive a seamless step from