Stereolithography (SLA)

Why SLA (Sterolithography)?

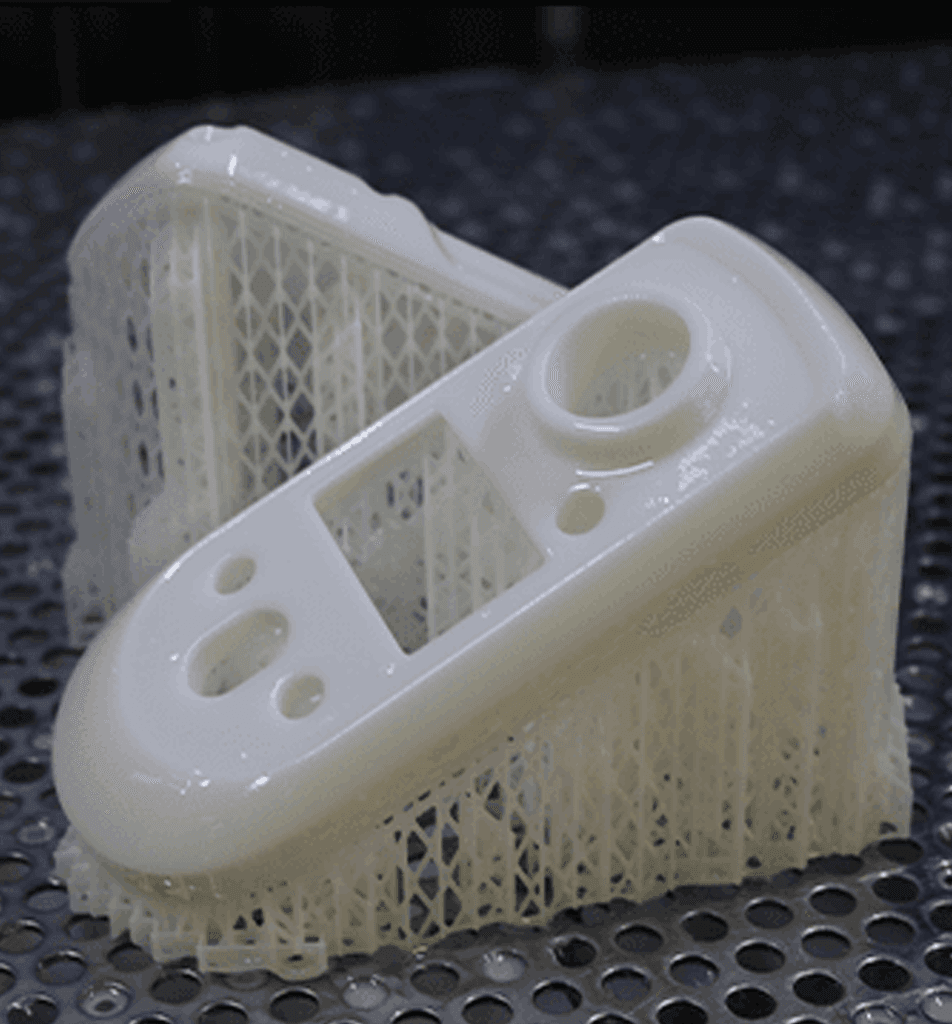

SLA (stereolithography) is the original 3D printing process — and still one of the most trusted for producing high-precision, visually impressive parts. Known for delivering exceptional detail and smooth surface finishes, SLA is ideal for applications where visual accuracy and fine features matter most.

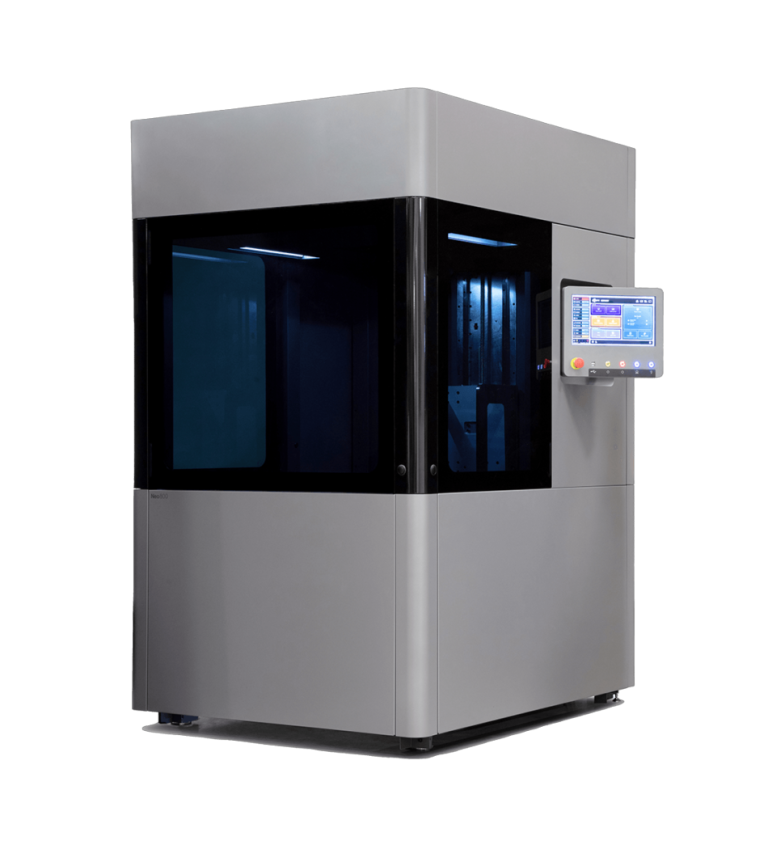

At Paragon, we operate three large-bed NEO 800 SLA machines — making us the only UK 3D printing service provider with this level of capacity and scale. These industry-leading printers allow us to deliver large, complex parts quickly and cost-effectively, without compromising on quality.

We offer a choice of advanced materials tailored to your application:

Somos® Evolve – A durable resin with excellent mechanical properties and a thermoplastic-like feel, ideal for functional prototypes and low-volume production parts.

Somos® Watershed – A clear, water-resistant resin with a smooth finish, perfect for transparent components, fluid flow testing, and applications in the medical and consumer sectors.

With rapid build speeds and a high-quality finish straight off the machine, SLA requires minimal post-processing, helping you reduce turnaround times and keep costs down.

-

Exceptional Detail and Accuracy Ideal for visual models, concept prototypes, and detailed presentations.

-

Large Format Capability Produce large parts or batches of smaller components with consistent surface finish and precision.

-

Functional and Visual Prototypes Validate designs with tough, reliable parts that closely replicate final production materials.

-

Perfect for Master Patterns Commonly used for tooling in processes such as vacuum casting and reaction injection moulding.

-

Efficient Low-Volume Production A cost-effective solution for short runs of complex, high-quality parts.

Our In-House Capabilities

Stratasys NEO 800

Quantity: 3

Production Quantities: 1 – 100’s

Build Size: 800 x 800 x 600