Multi Jet Fusion (MJF)

High-Strength, Functional Parts Delivered at Speed and Scale

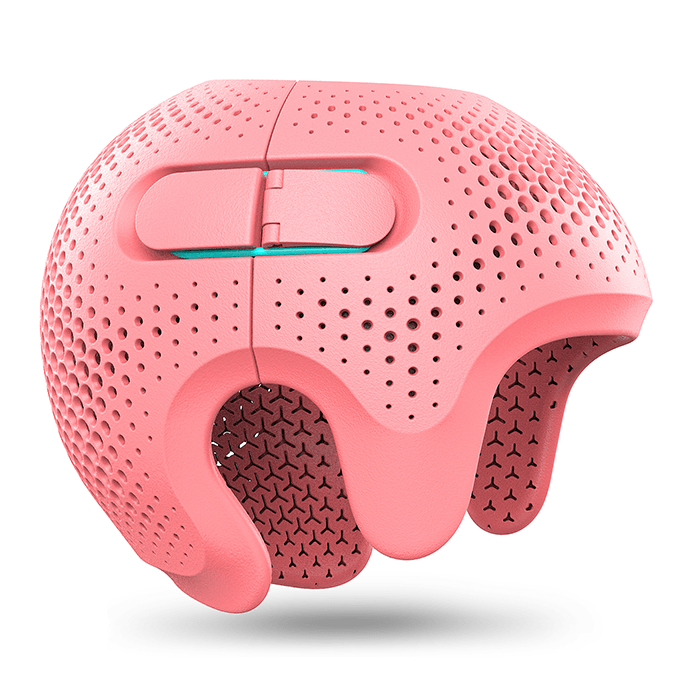

Multi Jet Fusion (MJF) is a powerful powder-bed 3D printing technology developed by HP, engineered for the production of robust, highly detailed components with excellent mechanical and thermal properties. Perfect for functional prototypes, short-run production, and complex geometries, MJF bridges the gap between prototyping and traditional manufacturing.

At Paragon Rapid Technologies, we use MJF to produce parts that are lightweight, durable, and production-ready—offering consistent performance even in demanding environments. With its ability to create finely detailed internal features, living hinges, and working assemblies, MJF is ideal for automotive, aerospace, industrial, consumer goods, and healthcare applications.

-

Strong, Functional Parts MJF produces high-density, isotropic parts with excellent strength and durability—suitable for both prototyping and end-use applications.

-

Fast, Scalable Production With short print cycles and batch-friendly processing, MJF supports fast turnaround times for high volumes and repeatable part quality.

-

Consistent Detail & Accuracy Capable of producing complex geometries with fine detail and dimensional accuracy, including intricate internal features and moving components.

-

Material Versatility Most commonly printed in PA12 (Nylon), offering excellent chemical resistance and thermal stability. Other materials available include PA11 and flexible elastomers, depending on application needs.

Our In-House Capabilities

HP MJF 4200

Lead time: 1 – 4 days

Build platform (mm): 380 x 284 x 380

Accuracy: to ± 0.3%

Print resolution: 1200 dpi

Wall thickness: 0.08 mm

Surface structure: Smooth and uniform with no support structures.

MJF parts are robust and suitable for end-use. Our post-processing includes PolyShot Surfacing to achieve a satin finish, and dye options in 170 colours.

HP MJF 5200

Lead time: 1 – 4 days

Build platform (mm): 380 x 284 x 380

Accuracy: to ± 0.3%

Print resolution: 1200 dpi

Wall thickness: 0.08 mm

Surface structure: Smooth and uniform with no support structures.

MJF parts are robust and suitable for end-use. Our post-processing includes PolyShot Surfacing to achieve a satin finish, and dye options in 170 colours.

HP MJF Post-Processing Unit

Our post-processing includes also includes PolyShot Surfacing to achieve a satin finish, and dye options in 170 colours.

Available Materials

PA 11

PA 11

Durable, detailed material ideal for prototypes, production, and complex moving parts.

Learn More