Medical and Healthcare

IMPROVE MEDICAL AND HEALTHCARE DEVICES MANUFACTURING AND PRODUCTION EFFICIENCIES

When it comes to saving or enhancing lives, breakthrough innovation can’t wait. The faster you can get your device to clinical trials—or your model into the operating theatre—the better the outcome for everyone.

Since 2003, we’ve been supporting the medical industry in bringing innovative devices to life. Our broad range of services, technologies, and specialist materials are tailored for the unique demands of the sector.

We’ve helped our customers innovate, develop, test, refine, and produce high-quality parts. We’ve guided them through concept visualisation, rapid design iterations, and faster decision-making. We’ve shortened product development cycles, found cost-effective production solutions, and adapted flexibly to their needs—ensuring satisfaction at every stage.

Because in medical innovation, time matters. And we make sure it’s on your side.

-

Unleash Your Creativity Explore multiple print and additive manufacturing options to bring even the most complex ideas to life.

-

Accelerate Time-to-Market Launch products faster with our rapid prototyping expertise and swift design iteration.

-

Reduce Inventory Costs Optimise spending with flexible production and low-volume manufacturing solutions.

-

Enhance Precision & Quality Improve accuracy with custom jigs, fixtures, and gauges designed for your production needs.

-

Select the Right Materials Access a wide range of biocompatible, sterilisable, heat-resistant, FDA- and REACH-approved materials.

Additive Manufacturing for Medical and Healthcare

Tool-free solutions for production parts

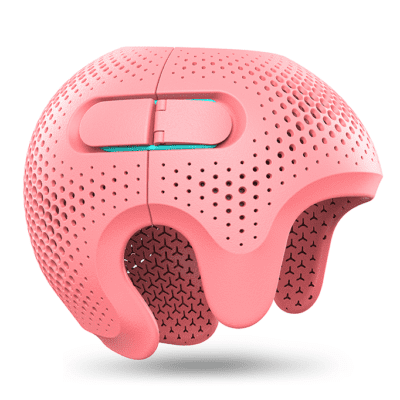

Additive manufacturing enables medical practitioners and product innovators to deliver customised healthcare solutions faster and more cost-effectively. We offer a range additive manufacturing technologies and medically approved materials to help you develop the products and processes required to improve patients’ lives. We have helped our medical innovation customers to create precise replicas of patient anatomy for surgical preparation; to personalise prostheses components; and to manufacture devices, models and equipment in low volumes.

Our revolutionary additive manufacturing technologies, Digital Light Synthesis™ and Multi Jet Fusion open up endless exciting production and customisation opportunities. Parts possess all the qualities of injection moulded plastics without the tooling costs. Materials are all biocompatible and the layering and resolution are so good you can even print wires in 1:72 scale!

Casting Solutions for Medical and Healthcare

Highly accurate, finely detailed, customised models, prototypes and end-use parts

ChatGPT said:

Accelerate innovation and improve quality with rapid validation prototyping and testing services, including 3D printing, vacuum casting, reaction injection moulding, and silicone casting. Our skilled technicians and model makers produce highly accurate, production-representative parts quickly and cost-effectively using low-cost tooling.

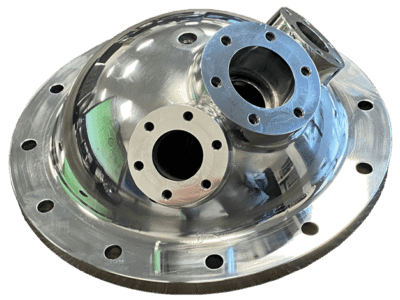

CNC Technologies for Medical and Healthcare

Our CNC machining capabilities give you the flexibility to adapt your designs, rapidly produce prototypes, and create manufacturing tools, all while achieving exceptional quality during production.

You can test parts and devices using engineering-grade materials with the same strength, weight, and feel as the final product, and even trial multiple design variations in parallel. CNC machining also offers a cost-effective solution for production volumes under 300, while on-demand component production helps optimise your supply chain and reduce warehousing costs. Additionally, custom gauges, jigs, and fixtures can enhance manufacturing efficiencies and ensure repeatable accuracy.