Heat Shielding

Precision Heat Shielding and Thermal Protection for Demanding Applications

Managing heat is critical in high-performance and high-stress environments — especially in industries such as automotive, aerospace, defence, and heavy machinery. At Paragon, we offer advanced thermal management solutions to help protect sensitive components, enhance performance, and ensure long-term reliability and durability.

We use a combination of advanced materials and manufacturing techniques to produce bespoke heat shields and thermal barriers that are lightweight, durable, and tailored to your specific requirements.

Our team provide direct input and support from prototype requirements and carry this through to production ensuring heat issues are addressed early in the process and relevant insulation materials are utilised.

-

Detachable Heat Shielding Detachable heat shields designed to insulate critical components such as exhaust systems, turbochargers, wastegates whilst bodywork from heat soak.

-

Integral Heat Shielding Insulation applied directly to the heat source, such as exhaust manifolds, turbochargers and mufflers to retain heat within the system, improving performance whilst protecting nearby components.

-

Thermal Insulation Materials We work with a wide range of advanced core materials suitable to withstand up to 1200°C leading to a significant temperature reduction such as AES Wools, Needlemat and Microporous insulation typically encapsulated within stainless steel or Inconel.

-

Lightweight Construction Our solutions combine weight-saving designs with robust performance - ideal for applications where space and mass are at a premium.

-

Prototyping To Production We produce 3D printed tooling and low density modelboard tooling to support with prototype volumes prior to commitment to CNC machined production press tooling.

-

Design and Manufacture Our in-house design team ensures we’re able to design tooling and parts maintaining full control of the process ensuring design revisions and tooling changes are carried out swiftly.

Depending on your application and maintenance requirements, heat shields can be designed as integral or detachable systems, each offering distinct advantages for performance, accessibility and longevity. At Paragon, we offer both integral and detachable heat shielding solutions tailored to meet the unique demands of your application. Understanding the difference helps ensure you get the right protection and performance for your components.

Integral Heat Shielding

Integral Heat Shields are built directly into the component or assembly. This creates a permanent, seamless barrier against heat, optimised for the exact geometry of your parts.

- Permanent protection with no risk of misalignment or displacement

- Optimised thermal efficiency through custom design

- Minimal maintenance – once installed, they provide ongoing protection

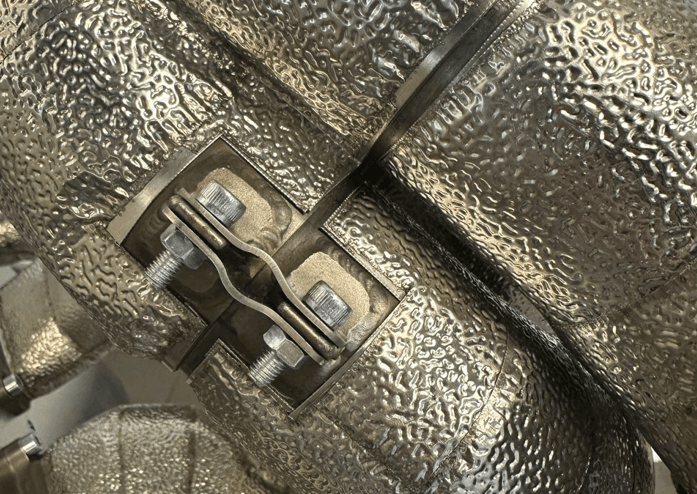

Detachable Heat Shielding

Detachable heat shields are separate components that can be installed, removed or replaced as required. They offer flexibility and accessibility for inspection, maintenance or upgrades.

- Easy removal and replacement, reducing downtime

- Adaptable to different components or updated designs

- Cost effective upgrades without needing to alter the base component

Whether you require robust, integrated protection or flexible detachable shielding, our team works closely with you to assess thermal requirements, material options and application conditions. We deliver bespoke heat shields that not only protect your components but also enhance performance and reliability across the full lifecycle of your product.