Energy, Oil & Gas

3D printing and casting of parts, props and models for stage and screen

The Energy, Oil & Gas sector is defined by scale—giant turbines, vast substations, and complex steel fabrications. At first glance, it may seem far removed from technologies like additive manufacturing and CNC machining.

But the reality is different. Every bespoke solution demands rapid prototyping, efficient production, and reduced costs. Time to market is just as critical here as in any other industry.

Since 2003, we’ve been helping innovators in the Energy, Oil & Gas sector transform the way they develop and deliver. Our advanced technologies and materials enable you to accelerate design cycles, streamline production processes, and enhance supply chain flexibility, all while reducing costs and driving true product innovation.

Just as you adapt to deliver value for your clients, we adapt to deliver value for you—time after time.

-

Mission-Critical Components Quick production of parts engineered to perform in the harshest environments.

-

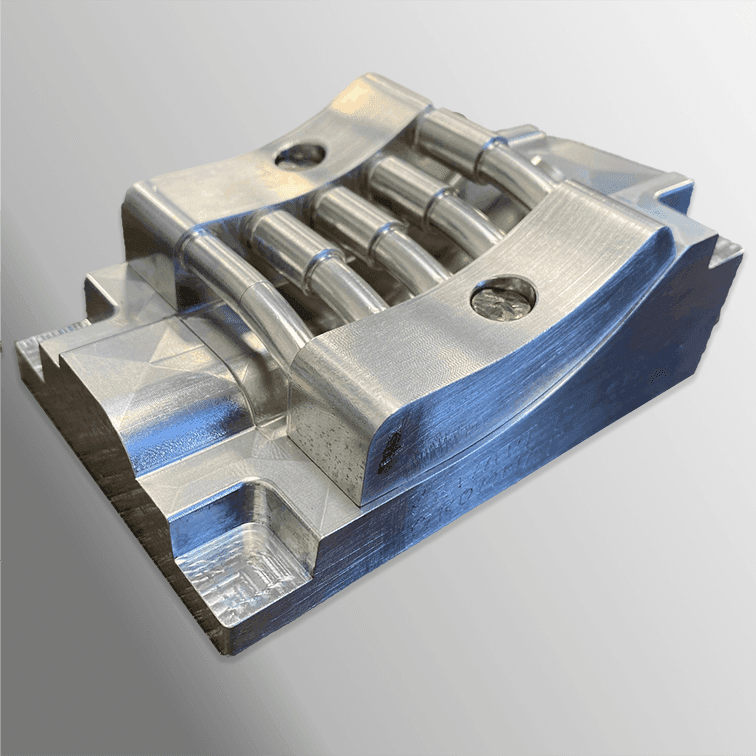

Rapid Tooling & Master Patterns Fast, cost-effective production of tooling to keep projects moving.

-

Tailored to Industry Standards Custom solutions designed to meet strict quality and compliance requirements.

-

Precision Jigs, Fixtures & Gauges Improve accuracy, repeatability and quality throughout your production process.

-

Lightweight & Sustainable Materials Environmentally friendly materials developed for durability and performance.

-

Scaled Training & Concept Models Detailed models for presentations, training and stakeholder engagement.

Additive Manufacturing for Energy, Oil & Gas

Tool-free solutions for prototyping and production parts with complex geometries

Parts produced with additive manufacturing can be found across the industry, from undersea applications to rooftop photovoltaic installations. Parts need to be tough, robust and durable. They have to withstand the rigours of both environment and activity. With an array of materials designed to stand up to such rigours, Additive manufacturing gives you the chance to realise your design sooner. It enables you to explore fit and functionality options without incurring tooling costs. And now, with materials specifically designed for production, additive manufacturing can be used to produce end parts without thinking about tooling.

Casting Solutions for Energy, Oil & Gas

Streamlined prototyping

Shorten production times for revolutionary ideas and enhance quality with a suite of rapid validation prototyping and testing services. Our services, including 3D printing, vacuum casting, reaction injection moulding and silicone casting, enable highly accurate, production-representative parts produced quickly and cost-effectively using low-cost tooling capabilities. Our materials include V0-rated plastics and polyurethanes, as well as those designed for deep sea usage and exposure to harsh environments.

CNC Technologies for Energy, Oil & Gas

Redefine your supply chain. Achieve efficiency. Increase productivity.

We offer an array of CNC technologies enabling fast turnaround of parts and prototypes. We also provide competitively priced support for manufacturing with precision-crafted parts and products in a variety of materials, including tool and mould production, jigs, fixtures and gauges. Through a contract management process, our mission is to help you shorten your supply chain and enable you to meet progressively tough design and production challenges. This can be achieved in isolation or in collaboration with our Additive Manufacturing and Prototyping capabilities