Marine/Subsea

ENGINEERING PRECISION AND PERFORMANCE BENEATH THE SURFACE

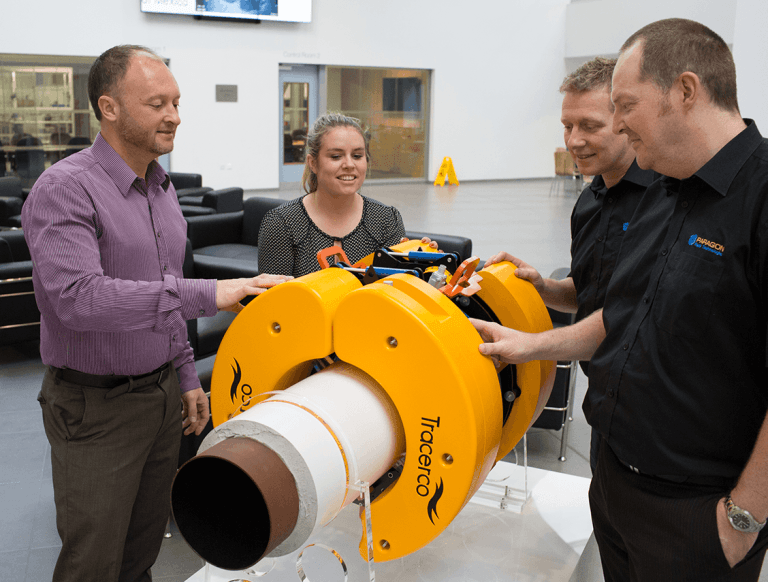

The marine and subsea sectors operate in some of the world’s most demanding environments — where durability, precision, and material integrity are critical. From deep-sea exploration and offshore energy systems to marine robotics and underwater infrastructure, Paragon Rapid Technologies delivers advanced prototyping and manufacturing solutions that help engineers innovate, test, and deploy reliable components built to perform under pressure.

We understand the challenges of corrosion, water ingress, and extreme pressures — and offer tailored manufacturing processes and materials to meet these demands from concept through to production.

-

Rapid Prototyping for Functional Testing Accelerate design validation and performance testing with fast, accurate prototype parts made from materials suited for marine environments.

-

Durable, Corrosion-Resistant Components Access a range of engineering polymers and metal alloys designed to endure saltwater exposure, pressure, and long-term operation.

-

Low-Volume and Replacement Part Production Bridge the gap between prototype and production with flexible manufacturing runs ideal for maintenance, spares, and retrofit applications.

-

Complex Geometry and Lightweight Design Utilise advanced additive and machining technologies to create intricate structures that reduce weight without compromising strength.

-

Material and Process Expertise Work with our team to identify optimal materials, finishes, and production routes for specific subsea performance requirements.

Additive Manufacturing for Marine/Subsea

Lightweight, Complex, and Corrosion-Resistant Parts on Demand

Harnessing advanced 3D printing technologies including SLA, SLS, DLS, and MJF, Paragon enables rapid iteration and production of complex components for underwater and offshore use. Our additive solutions deliver lightweight yet robust parts ideal for housings, connectors, and hydrodynamic structures, with a range of materials suitable for high humidity and saltwater exposure.

Casting Solutions for Marine/Subsea

Durable, Flexible, and Cost-Effective Components for Harsh Environments

Our Vacuum Casting and RIM (Reaction Injection Moulding) services provide durable polyurethane components for prototyping and low-volume production. These processes are ideal for replicating end-use plastics, seals, or protective housings, offering flexibility in material properties such as impact resistance, sealing capability, and UV stability.

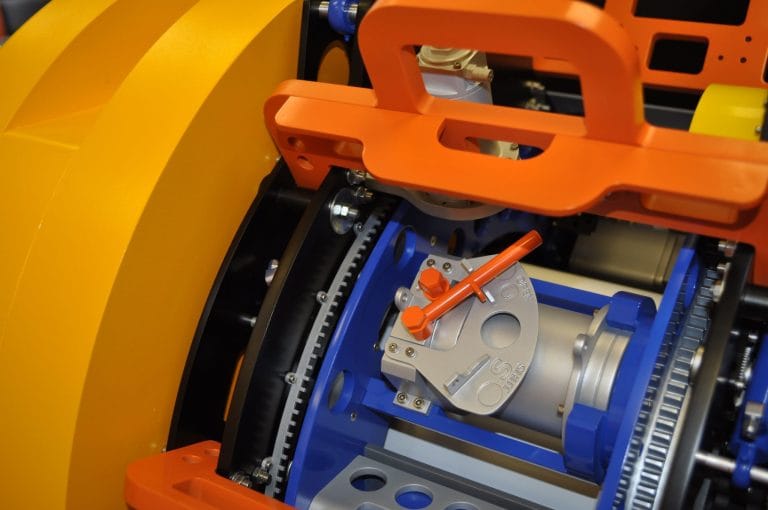

CNC Technologies for Marine/Subsea

Precision-Machined Metal and Plastic Parts Built to Withstand the Deep

With precision CNC machining capabilities, Paragon produces metal and polymer components that meet tight tolerances required for demanding marine applications. From corrosion-resistant alloys to engineering-grade plastics, our machining expertise ensures consistent quality and performance for critical subsea assemblies and hardware.