Industrial/Engineering

From Concept to Production: Precision Solutions for Industrial and Engineering Innovation

Your clients come to you because they believe you are the best at turning visions into reality. To maintain that standard, you need a partner who understands product development from the first CAD concept to full-scale manufacture.

Since 2003, we have been helping design agencies, engineering firms, and industrial companies bring their ideas to life. Our state-of-the-art technologies, materials, and services allow you to explore concepts, create functional prototypes, and manufacture devices and products in low to mid-volumes.

Industrial products may seem simple, but like all sectors, they are being transformed by digital technologies. From robust filtration systems to precision parts for production-line robots, development speeds are faster, production processes are more efficient, and the race to market has never been more intense.

Our technologies enable you to rethink product innovation. They streamline your development cycles, simplify your production processes, and allow you to shrink and flex your supply chain while enhancing the value of your industrial and engineered products.

While you focus on flexibility and cost-efficiency for your customers, we focus on delivering the same for you—helping you stay ahead in an increasingly competitive market.

-

Push Creative Boundaries Explore limitless possibilities with our versatile 3D printing and additive manufacturing options.

-

Launch Products Faster Achieve first-to-market success with our rapid prototyping expertise.

-

Reduce Inventory Costs Optimise production with our low-volume solutions to keep costs under control.

-

Enhance Quality and Precision Improve accuracy and consistency with custom jigs, fixtures, and gauges.

Product development support and low volume manufacturing for companies in the industrial products sector including:

-

Filtration and Environmental Systems

-

Metrology and Instrumentation

-

Robotics and Automation

-

Tooling, Construction and Hardware

-

Wearables and Safety Equipment

-

Industrial Machinery and Equipment

Additive Manufacturing for Industrial/Engineering

Tool-free solutions for production parts

Consumer products need to be functional, ergonomic, and visually striking. Additive manufacturing lets you realise designs faster, test fit and function without tooling costs, and finish parts to exceptional standards—overmoulded, painted, or printed with custom graphics.

With production-grade materials tough enough for daily use, our Digital Light Synthesis™ and Multi Jet Fusion technologies deliver end-use parts with all the qualities of injection-moulded plastics—without the tooling. Biocompatible and precise enough for fine details, the possibilities are endless.

Casting Solutions for Industrial/Engineering

Quick turnaround on prototypes and low-volume production parts

Bring your ideas to market faster and with greater confidence using our comprehensive suite of rapid validation, prototyping, and testing services. From 3D printing and vacuum casting to reaction injection moulding (RIM) and silicone casting, we provide the tools and expertise to turn concepts into highly accurate, production-representative parts.

Our experienced technicians and skilled model makers ensure each part meets your exact specifications, enabling functional testing, fit verification, and design validation before committing to full-scale production. By leveraging low-cost tooling solutions, we deliver high-quality prototypes quickly and cost-effectively, helping you reduce development cycles, mitigate risk, and accelerate time-to-market.

CNC Technologies for Industrial/Engineering

CNC Technologies for Industrial/Engineering

Lower costs and assure quality with end-to-end supply chain management, and faster tooling and part production times.

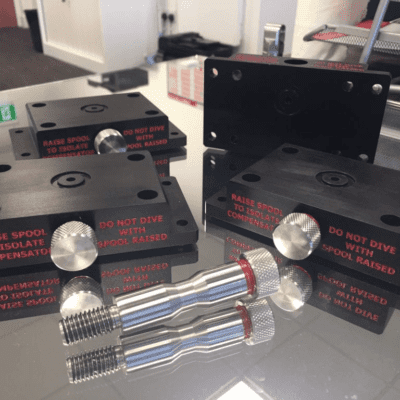

Successful consumer product development requires speed to market and accuracy. A supplier who can help you evaluate materials, develop your prototypes, deliver on low volume manufacturing and create production tools quickly and cost-effectively will be a key factor in helping you beat your competition to market. Our engineering and contract managed CNC capabilities allow you to flex your designs, produce prototypes quickly, develop and modify tools for manufacture and achieve outstanding quality at the manufacturing stage. They include gauges, jigs and fixtures, contract manufacturing of component parts, and tooling and mould modifications.