Aerospace

Assisting aerospace innovation with prototyping, product development and end-use parts

The aerospace industry continues to push the boundaries of innovation, with technologies such as additive manufacturing driving efficiencies in the production of lightweight, environmentally conscious, and complex parts.

As an aeronautical design engineer, you need a product development partner ready to invest in these technologies and deliver prototype parts that meet your performance and efficiency goals without compromise.

Our teams of highly skilled engineers produce precision parts, prototypes, tooling, and mould modifications of exceptional quality. We understand the importance of adhering to strict customer specifications and provide a fully managed, end-to-end service, ensuring consistent quality from materials selection to tight tolerances.

-

Concept Visualisation & Design Optimisation Use advanced techniques like Vacuum Casting, CNC machining, and 3D printing to refine designs and explore cabin layouts before production.

-

Additive Manufacturing for Placeholder Parts Quickly produce like-for-like components to support assembly and construction, saving time and reducing risk.

-

Rapid Tooling & Master Patterns Deliver cost-effective tooling solutions and master patterns to accelerate prototyping and low-volume production.

-

Custom Jigs, Fixtures & Gauges Enhance production quality and accuracy with bespoke tools designed for repeatability and precision.

Product development support and low volume manufacturing for companies in the aerospace sector including:

-

OEM's

-

Tier 1 Suppliers

-

Tier 2 Suppliers

-

Aircraft Seating

-

Aircraft Medical Equipment

-

Interior Designs

-

Research & Development

Additive Manufacturing for Aerospace

Our 5-axis technology delivers precision and versatility, enabling:

Post-machining of production models

Low-volume manufacturing of metal machined components

Production of styling models, gauges, jigs, fixtures, and compression tooling

All with working dimensions up to 2500 x 1500 x 1200 mm.

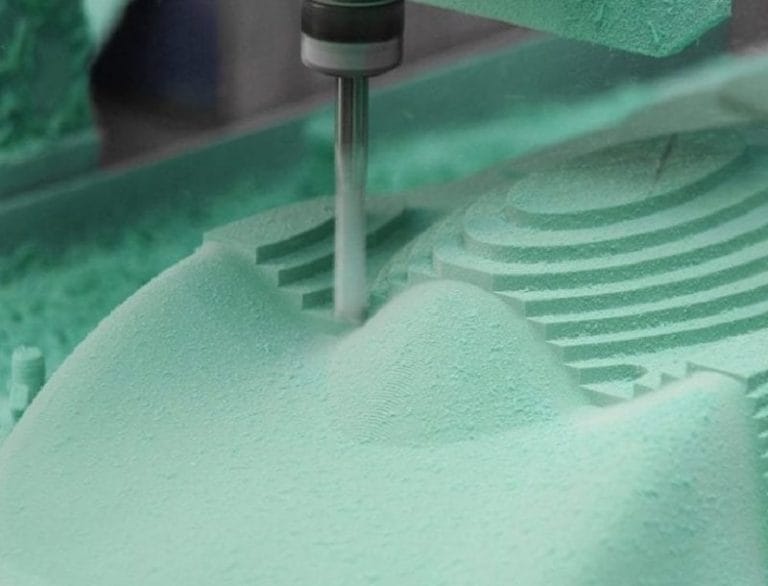

3-Axis Machining

Our 3-axis capability provides efficient milling and cutting of steel, aluminium, ABS, model board, foam, and nylon. Customers benefit from competitively priced, high-quality, low-volume metal components, as well as styling models, gauges, jigs, fixtures, and compression tooling up to 1626 x 813 x 762 mm.

Moulding Solutions for Aerospace

Our state-of-the-art CNC technology makes it possible to produce new or customised parts with complex geometries—quickly, precisely, and cost-effectively.

At the core of our CNC operations is a commitment to collaboration and meticulous contract management. We work closely with you to select and validate the ideal materials and machining methods, ensuring faster production starts, exceptional accuracy, long-lasting performance, and consistent quality in every batch.

With decades of experience, an unwavering dedication to quality, and a highly responsive engineering team by your side, we’re ready to guide you seamlessly through the entire production process.

CNC Technologies for Aerospace

Tooling is a critical stage in the product development cycle and a cornerstone of the manufacturing process. The speed to market, quality, repeatability, and accuracy of your component, prototype, or finished product all depend on the precision and performance of your tooling.

We help manufacturers reduce labour and quality costs while accelerating delivery times. Our comprehensive tooling solutions are designed for the demands of modern production, supported by large-gantry, state-of-the-art 3-, 4-, and 5-axis CNC machines. These capabilities allow us to produce assembly tools, RIM tools, press tools, and specialist dies and moulds—engineered for accuracy, durability, and efficiency.