CNC Machining

Redefine your supply chain with increased efficiency and productivity through quality assured CNC milling and turning.

Today’s companies face unprecedented pressure to innovate at speed. Success depends on getting your product in front of its target audience as quickly as possible—while meeting increasingly demanding design and production requirements without driving up costs.

Our comprehensive CNC machining services enable rapid turnaround for both prototypes and end-use parts. With CNC milling and turning in a wide range of engineering-grade materials, we offer cost-effective manufacturing solutions with exceptional precision. For high-volume production, our bespoke jigs, fixtures, and gauges design service supports rigorous quality control. We can also tackle your toughest design and production challenges independently or in collaboration with our Additive Manufacturing and Prototyping capabilities.

Since 2003, we’ve delivered quality, precision CNC engineering to customers across diverse sectors. Our technical expertise and deep process knowledge ensure the highest manufacturing standards. When it’s time to move into production, our tooling and moulding capabilities guarantee flawless runs – every time.

Machining & Turning

Our 5-axis technology delivers precision and versatility, enabling:

Post-machining of production models

Low-volume manufacturing of metal machined components

Production of styling models, gauges, jigs, fixtures, and compression tooling

All with working dimensions up to 2500 x 1500 x 1200 mm.

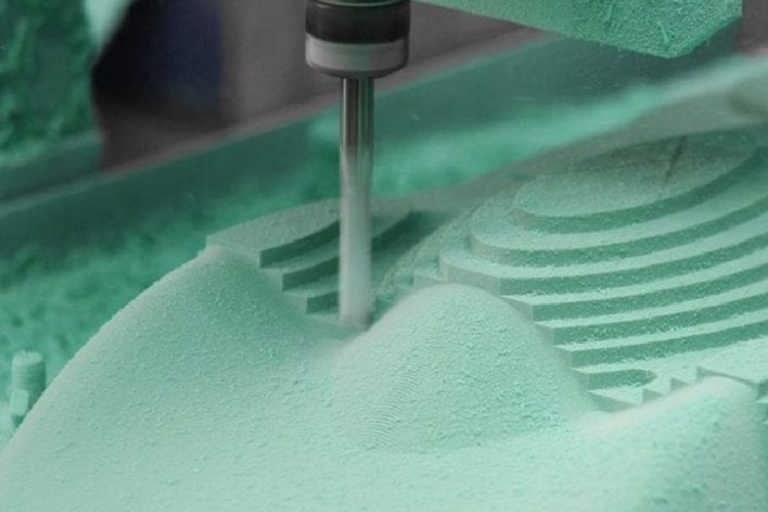

3-Axis Machining

Our 3-axis capability provides efficient milling and cutting of steel, aluminium, ABS, model board, foam, and nylon. Customers benefit from competitively priced, high-quality, low-volume metal components, as well as styling models, gauges, jigs, fixtures, and compression tooling up to 1626 x 813 x 762 mm.

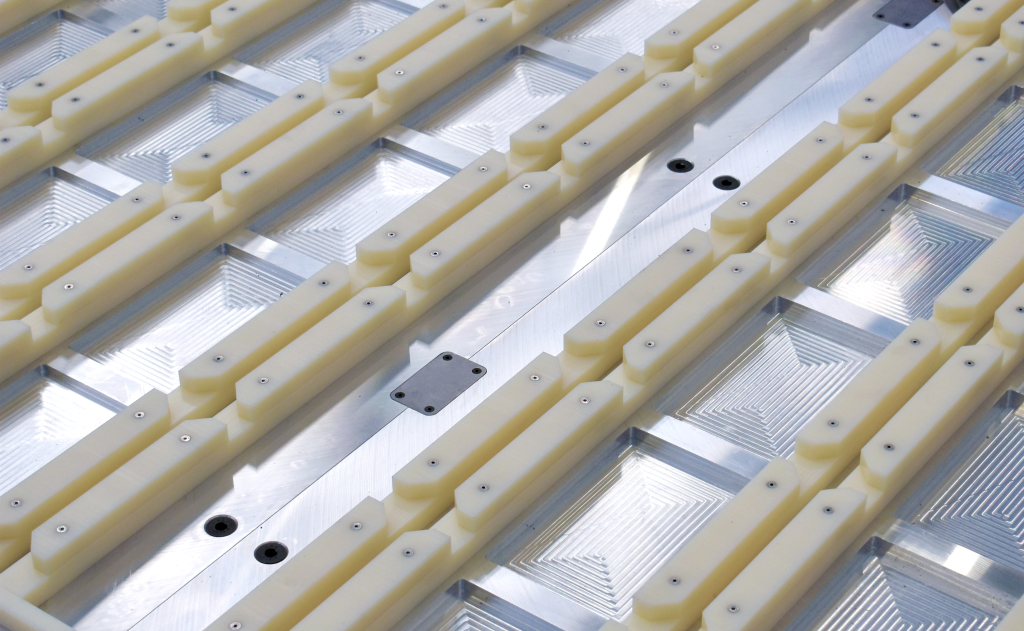

Gauges, Jigs & Fixtures

We understand the pressure to keep manufacturing costs low while maintaining consistently high quality.

Our CNC technologies, combined with the expertise of our design engineers, allow us to produce the gauges, jigs, and fixtures that are vital to productivity and quality control. Every project is carried out to stringent quality standards, ensuring durable, stable, and repeatable parts you can rely on.

Using the latest FAROArm technology, we provide full validation reports against original parts, giving you complete confidence in accuracy. And with short lead times, competitive pricing, and exceptional customer service built into our own manufacturing process, we deliver the performance you need—without compromise.

Component Parts

Our state-of-the-art CNC technology makes it possible to produce new or customised parts with complex geometries—quickly, precisely, and cost-effectively.

At the core of our CNC operations is a commitment to collaboration and meticulous contract management. We work closely with you to select and validate the ideal materials and machining methods, ensuring faster production starts, exceptional accuracy, long-lasting performance, and consistent quality in every batch.

With decades of experience, an unwavering dedication to quality, and a highly responsive engineering team by your side, we’re ready to guide you seamlessly through the entire production process.

Tooling, Moulds and Dies

Tooling is a critical stage in the product development cycle and a cornerstone of the manufacturing process. The speed to market, quality, repeatability, and accuracy of your component, prototype, or finished product all depend on the precision and performance of your tooling.

We help manufacturers reduce labour and quality costs while accelerating delivery times. Our comprehensive tooling solutions are designed for the demands of modern production, supported by large-gantry, state-of-the-art 3-, 4-, and 5-axis CNC machines. These capabilities allow us to produce assembly tools, RIM tools, press tools, and specialist dies and moulds—engineered for accuracy, durability, and efficiency.

Inspection

We provide comprehensive quality inspection and precision rework services.

Using FAROArm Edge technology to UKAS national standards, we measure every gauge, jig, fixture, tool, and part for absolute accuracy before it leaves our facility. Capable of handling both large and small components, we ensure quality control and assurance at every stage of the manufacturing and supply process—giving you complete confidence in the end result.