Digital Light Synthesis (DLS™)

Production-Grade 3D Printing with Speed, Strength, and Surface Perfection

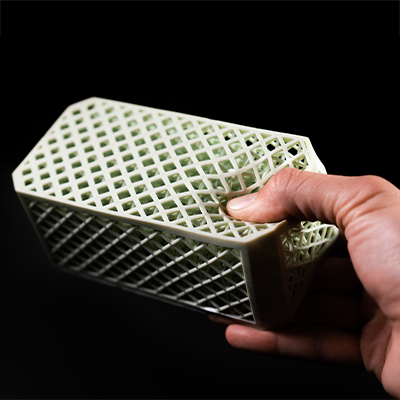

Unlock the power of Digital Light Synthesis (DLS), a next-generation 3D printing technology that delivers end-use parts with exceptional strength, accuracy, and surface finish. Ideal for both prototyping and low-to-mid volume production, DLS uses light and oxygen to rapidly cure advanced liquid resins into solid parts—without the layer lines or mechanical weaknesses associated with traditional additive manufacturing

At Paragon Rapid Technologies, we harness Carbon’s DLS technology to produce high-performance parts that rival injection moulding in quality, with significantly reduced lead times. Whether you need flexible elastomers, durable engineering-grade plastics, or biocompatible resins, DLS offers a material portfolio that’s fit for some of the most demanding industries, including automotive, aerospace, medical, and consumer products.

-

Exceptional Mechanical Performance Parts printed using DLS are isotropic and production-grade, offering strength, durability and consistency in every direction - ideal for functional prototypes and end-use components.

-

Smooth Surface Finish DLS eliminates visible layer lines, producing parts with clean, smooth finishes right off the printer, reducing or removing the need for post-processing.

-

High-Speed, Scalable Production Faster than many traditional 3D printing processes, DLS enables rapid turnaround of complex geometries and supports short-run or bridge manufacturing needs.

-

Diverse Material Range Access a wide selection of materials including rigid, flexible, heat-resistant, and biocompatible resins—suitable for applications ranging from seals and housings to personalised medical devices and consumer wearables.

Our In-House Capabilities

Carbon M2 Printer

Quantity: 2

Production Quantities: 10s – 10,000s

Build Size: 189 x 118 x 326

Carbon ‘Smart Part Washer”

The Carbon Smart Part Washer provides an effective, repeatable, and traceable washing process with a cycle optimized according to print data collected via the platform (or adapter) NFC tag.

Maximize Part Quality and Yield

With optimized wash protocols, every part is consistently cleaned with minimal manual labor, resulting in lower per-part cost.

Smart and Connected

Our next-generation software provides automatic, part-specific wash protocols, process control data for part traceability, and regular software updates.

Manufacturing at Scale

The Smart Part Washer delivers simple, repeatable part washing, enabling manufacturing at scale and environmental stewardship.

Rigid Materials

EPX 82

EPX 86FR

EPX 150

EPX 150

Exceptional temperature and chemical resistance, functional toughness, steam sterilizable

Learn More